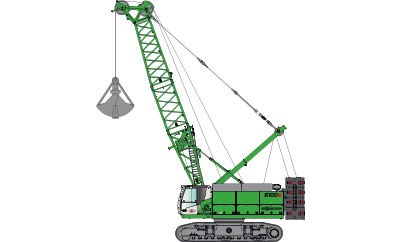

New duty cycle crawler crane class: 100 t duty cycle crawler crane designed for special foundation work and more

The robust SENNEBOGEN heavy-duty duty cycle cranes are designed for extreme challenges. With the new SENNEBOGEN 6100 E, the manufacturer is expanding its product portfolio to include a new performance class with 100 t operating weight and a wide range of tasks, from special foundation work and mining to soil compaction and dropball and demolition applications. The machine slots in between the 70 t and 140 t duty cycle cranes within the extensive SENNEBOGEN product portfolio.

As a duty cycle crane of the current E-Series, the new SENNEBOGEN 6100 E was designed especially for demanding, dynamic applications with a wide variety of equipment. Thanks to its robust construction, a powerful multi-circuit hydraulic system, and the strong slewing drive, the 100-tonne duty cycle crawler crane is particularly well-suited for special foundation work. Applications with leaders or diaphragm wall grabs can be realized just as reliably as the operation of hydraulic piping machines with rope grabs for well excavation and special excavation work. Here, two standard 20 t freefall winches provide impressive traction. These winches are also available in heavy-duty 27.5 t and 30 t versions as an option. As a true duty cycle crawler crane, the machine features reliable winch synchronization and can also be equipped with special control technology for automated free-fall operation for dynamic soil compaction.

Advantages of the Machine

With a wide variety of equipment variants, the SENNEBOGEN 6100 E can be individually configured according to customer requirements. The machines offer convincing performance not only in terms of stability. The telescopic crawler undercarriage with removable tracks, allows not only different track gauges to be realized with ease, but also reduces the transport weight to less than 40 t.

This machine comes to market just in time for bauma with the latest generation of engines compliant with emission stage 5. In addition to the 451 kW stage 5 engine, a stage 3 engine version with 447 kW is also available.

The modern Maxcab comfort cab provides the operator with an ergonomic work environment. The cab can be optionally designed for inclination by 15 degrees in order to allow an even better view of the attachment and the work environment. The safety of operators and drivers is also a key concern with the new 6100 E. Numerous walkway options, a fall arrester on the boom and a continuous uppercarriage railing are just some of the features available.

Machine in use

Press images

Press images

Press images