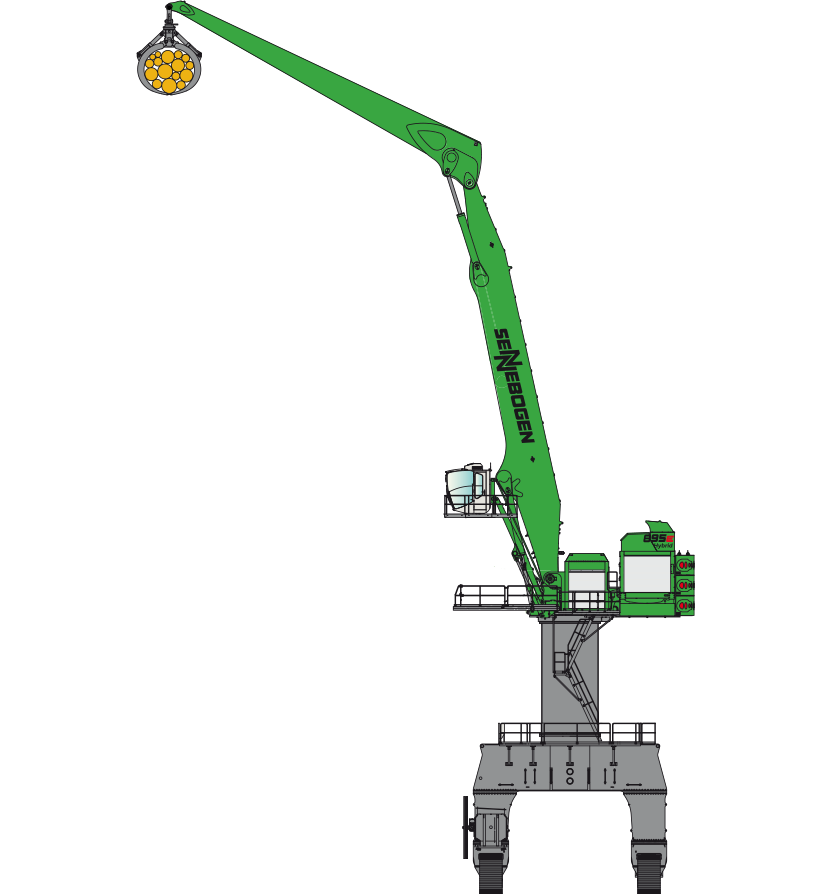

The world's largest material handler: The new SENNEBOGEN 895 E sets new standards

SENNEBOGEN will be presenting the largest material handling machine ever produced to the public during the bauma 2019: the new 895 E. The gigantic machine boasts an impressive operating weight of nearly 400 t and ranges of up to 40 m. SENNEBOGEN will be presenting the gigantic material handler on the company premises in Straubing during the bauma week, thus setting new standards in demanding material handling.

Bigger, taller, further – that’s how one could summarize the development of the hydraulic material handling machines over the past few years. Bavarian machine manufacturer SENNEBOGEN is taking it one step further with the largest material handling machine in the world. With a total system output of over 750 kW and an operating weight of nearly 400 t, there is no other material handling machine like it on the market. The machine stands on the company premises in Straubing just in time for the bauma.

Interested customers can sign up for a tour of the premises and transport to Straubing through the relevant SENNEBOGEN sales partners. In fact, a visit will pay off double because, In addition to the 895 E, the latest version of the 9300 E port mobile crane will also be on show.

Specialist for all harbor requirements with Green Hybrid

As a hydraulic material handling machine, the new SENNEBOGEN 895 E is at home in the largest harbors of the world. With a maximum range of 40 m, the machine boasts impressive performance not only in bulk cargo handling, but also in container handling at ranges of up to 28 m. Even the heaviest loaded goods (such as steel coils) can be lifted at short ranges with a load capacity of up to 50 t. This makes the machine a specialist for all handling tasks at the harbor.

The new 895 E also has the Green Hybrid energy recovery system, as well-known and proven from the SENNEBOGEN 855 E to 875 E machines. Two additional hydraulic cylinders mounted between the two lifting cylinders on the boom store the energy produced when the boom is let down in compressed gas cylinders at the rear of the machine. This accumulated energy is then available for the next lift. The principle can be compared to a spring being compressed and then releasing its energy when it is allowed to expand. As such, the machine works in an extremely efficient and resource-friendly manner in spite of its immense size.

Modular design – versatile solutions

SENNEBOGEN has made use of a proven modular principle for many decades. This enables the customer to individually optimize the machine to the handling requirements and circumstances on site.

For instance, the new 895 E comes with a total of four equipment lengths from 28 m to 40 m. A 563 kW diesel motor and a 500 kW electric motor are available as drive options. Three versions of undercarriages are available as standard, from a mobile undercarriage with 14 sets of wheels, to a crawler portal version and a rail portal solution.

Convenient maintenance and ideal access

Great attention was paid to make sure the big machine would be maintenance-friendly during the development of the material handling machine. One new feature is the accessible power pack unit, which offers excellent access to all maintenance points and the control and drive components. The power pack itself conceals major advantages in its very configuration. Even bulky components are safe and easy to replace if necessary thanks to the openable roof cover.

The world’s biggest material handler provides the operator with a unique feeling of spaciousness in the comfortable Portcab, with an eye level of up to 22 m. Thanks to the variable Skylift cab elevation, the cab can move over 11 m of travel, giving the operator an unobstructed view of his work area at all times. Access to the undercarriage is also safe and easy thanks to additional railings and steps.

Machine in use

Press images

Press images

Press images