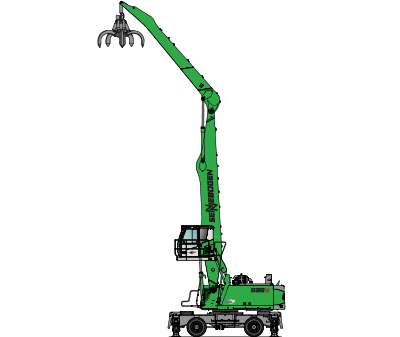

Bulk handling in the port: First test reports of the new 47 t material handler 835 G Hybrid

Powerful, precise and extremely fast – these were the words used by the proud test operators to describe the 835 G Hybrid material handler, the new 47 t model produced by SENNEBOGEN. With a handling capacity of around 800 t per hour, it is a pioneer in its machine class and is now defining new standards in its special field, the demanding material handling business: whether in inland ports, in scrap yards or in the steel mill. Find out what makes it so special in the report from the testers who put it through its paces.

Three endurance tests for the new machine

The opportunity to test drive a new machine at maximum power, to explore its full potential: Three loyal SENNEBOGEN customers were invited to exclusively challenge the 835 G Hybrid material handler. Their impression of the new specialist for inland ports, scrap operations and steel mills? Precision meets operator and service comfort, combined with unparalleled performance and efficiency.

Simulation of a loading situation in the port

Maximilien Gras, a long-standing SENNEBOGEN customer, traveled from France to Germany. The managing director of the port service provider and machine rental company SARL Gras looks back on many years of experience with various material handlers from different manufacturers. It was without hesitation that he himself sat down at the joysticks of the new SENNEBOGEN 835 G-Series. The machine was tested on the training grounds of the SENNEBOGEN Academy, as these are the ideal conditions for either training operators or simulating a realistic loading situation from everyday life in a port: in this case, it involved a slewing angle of 80° when filling a hopper, 1.7 t/m³ bulk density of the material, and a 2.2 m³ clamshell bucket. Back from his test drive inside the cab, the passionate machine operator concludes:

"I am simply thrilled with the performance of this machine: On the one hand, the support of the Green Hybrid system now enables a completely different motion sequence. With the additional force of the third hydraulic cylinder between the two lifting cylinders, the boom moves upwards almost by itself after the material has been picked up. This means that even in this machine size, superimposed slewing and stroke movements can be carried out that enable a completely different dynamic and speed. At peak times, I can reach about 800 tons per hour. That is really unique in this machine class! On the other hand, as a business man, I am of course pleased to see the positive effects of the decreased diesel consumption caused by the recuperation technology: 30% less fuel for this output – that's quite a statement to the market."

Material handler with a strong focus on operator and service comfort

The second and third test cycles of the 835 G Hybrid were an excellent opportunity to examine the machine in detail in the scrap yard and in the steel mill. In addition to the lower consumption, due to SENNEBOGEN's Green Hybrid recuperation technology, the features developed specifically for the operator stood out in particular in the next case. Ferid Ibralic, an experienced machine operator at Rohstoffverwertung Regensburg GmbH, commented:

A comparison between the two E-Series and G-Series machines

After arriving at the Lechstahlwerke facilities, Germany, the special 835 G Hybrid has now been put to work in demanding heavy-duty operations during EAF (electric arc furnace) slag recycling. After several days of use on the site, Benjamin Kinlinger, Division Manager of EAF Slag Processing at Max Aicher Umwelt GmbH, states:

"We now have a direct comparison between the E-Series and G-Series machines, and we've definitely found a few essential changes here: I've noticed that the machine is even more service-friendly. The daily walk-around and machine check can be done safely and almost completely from the ground by our employees. Every tank level indicator, every mechanical component, and even the electrical installation are easily examined, thanks to the clear arrangement of the components. This saves a lot of time! And: as in the past, SENNEBOGEN attaches great importance to the fact that with the new 835 G Hybrid, we ourselves can carry out uncomplicated and independent diagnostics and maintenance steps. For us as a service company inside the constantly running steel mill this is a striking advantage to avoid downtime!"

Jobsite Video

Machine in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images