Combined transport: 835 G Hybrid supports the shift from classic road transport to waterway shipping

SENNEBOGEN's customer L'Ortye, a logistics company in the southern region of the Netherlands, is the hub of the intermodal transport chain in Dutch sugar production. The sugar beets project aims to reduce the number of trucks by up to 8,000 by using inland vessels for intermodal transportation. When it comes to switching from classic truck transport to waterways, L'Ortye relies on the Dream Team, the new 835 G Hybrid and the 355 E telehandler. The company which is specialised in handling bulk materials owns three port locations at the Juliana Canal in Maastricht and Stein, and uses several green SENNEBOGEN machines there.

Netherlands benefits from high share of inland waterway freight transport

Official statistics show that in the Netherlands, the share of freight transported by inland waterways was already very high in 2019, at 42.7%, compared to the European average of a mere 7%. The direct effects are visible to all commuters on a daily basis: a high density of trucks on highways, roads and in the inner cities. So-called combined or intermodal freight transport can be mentioned as a promising solution, which bundles the advantages of several different modes of transport: By switching from land to water, to rail, the overall traffic load is reduced, less pollutants and noise are produced, and at the same time, more traffic safety is ensured. The inland waterway can also be used to send larger volumes of freight from A to B. This saves time, money and protects the environment.

Goal: save 8,000 trucks and 20% of CO2 emissions by inland shipping

A project is currently underway in the Netherlands to massively reduce truck traffic during the sugar beet season. 8,000 trucks and thus around 20% of CO2 emissions are to be saved by using barges to extract the white gold. A feat that requires a highly effective process chain and special equipment.

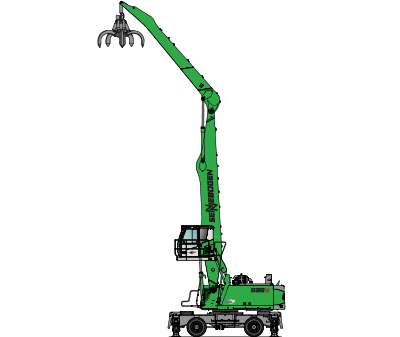

4 t of sugar beets per minute processed by the new SENNEBOGEN 835 G Hybrid and 355 E

Around 270,000 tons of beets will be handled at L'Ortye's quay in Maastricht during this year's beet campaign from September to the end of December, to be shipped by water to the sugar factory. That means 4 tons of beets per minute are loaded by L'Ortye. During the campaign, every minute matters to ensure that the evaporation process is not interrupted when refining sugar. In this way, the harvesting, transport and logistics companies, and barge operators all work together to ensure a continuous flow of material to the sugar factory in the Netherlands. Right in the middle of the supply chain, the 355 E telehandler and the new SENNEBOGEN 835 G Hybrid take care of the central transfer of beets to the barge.

Only results count: Quality management, loading speed, low emissions

108 days are available to transport the harvest safely to the sugar factory. Every seven minutes, the next truck shows up at L'Ortye, delivering another 35 tons of beets. The SENNEBOGEN 355 E not only prepares the material for loading; equipped with a pushing blade including a sampling device, the telehandler is also responsible for quality control. This ensures that the beets delivered meet the appropriate quality criteria for further processing. Because as soon as the SENNEBOGEN 835 G Hybrid loads them onto the barge, their proof of origin is eliminated.

machines fit perfectly into the concept of value-added logistics and services

The new 835 G Hybrid material handler is also tailor-made for this project: fuel-saving technology, powerful work cycles and precise control behavior. In particular, the Green Hybrid recuperation technology, which restores around 30% of the energy required in each cycle, combined with a 188 kW diesel engine with Stage V emissions standard, ensures clean, CO2-reduced operation. All in all, the machines fit perfectly into their concept of value-added logistics and services. Crushing, screening, blending, packaging and quality control are all examples of L'Ortye's daily activities.

Machine in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images