Port logistics simplified: Customized SENNEBOGEN material handler for Swedish port operator

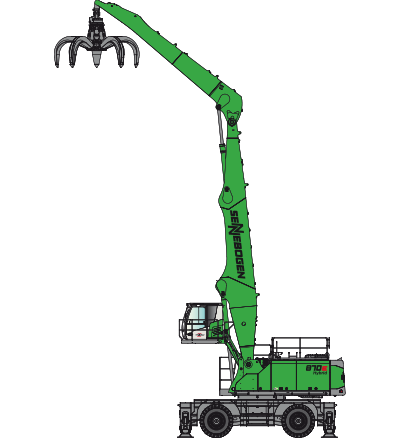

Back in 2018, Delta Terminal put a customized SENNEBOGEN material handler into operation in the port of Söråker, Sweden, and now reports on the experience gained with the machine: Thanks to the mobile undercarriage, the 24 m equipment, and an excellent visibility for loading and unloading ships, the material handler proved to be the ideal solution for their port. Designed for the harsh climatic conditions of the far north, the 870 E copes with the maritime weather and significant temperature changes in an unparalleled manner. Delta Terminal's conclusion? When it comes to investments like this, it pays off to go into the smallest detail during the planning process and consider the long-term benefits.

More lightweight than the previous solution, more reach, high maneuverability, a particularly robust design and the necessary visibility for ship loading - these were Delta Terminal's requirements for its 870 E material handler in Söråker, Sweden. "Along our 180 m quay, we handle around 50 ships a year with a hull depth of up to 7 m," explains Johan Stenström, Operations Manager at Delta Terminal, recently. Therefore, the port handler has to be stable on the quay in order to position large loads with pinpoint accuracy, especially inside the ship's hull. Here, the special mobile undercarriage from SENNEBOGEN entered the picture: thanks to its star-shaped undercarriage construction with pivoting outriggers, it creates a particularly large support base of around 63 square meters. In this way, both the weight of the 120-ton machine and the forces occurring during slewing are ideally transferred to the ground, and the ground pressure is evenly distributed. As a mobile version, the large port machine remains extremely maneuverable and can be used flexibly throughout the site, whether on the quay or at the storage facilities.

15 percent more handling capacity in import and export business

"Every year, we move around 200,000 tons of material from water to trucks or vice versa. For us, it was very important to be able to cover the great variety in the port business in the most efficient way. Above all, we now benefit from the extra reach that the SENNEBOGEN 870 E gives us!" adds Johan Stenström, who is responsible for port logistics at Delta Terminal.

Industrial waste, general cargo and timber are all part of the Swedish company's daily business. However, bulk materials such as salt, magnesium or quicklime make up the largest share of the material to be processed each year, roughly 60%. "Thanks to its 24 m equipment with a bent boom, we now not only have more reach, but also a greater reach depth. As a result, we position the material with more ease and speed, also due to the fast work cycles of the machine itself."

Still in the decision-making phase: test drive at a comparable application

To gain a complete understanding of the SENNEBOGEN machines, Delta Terminal was invited to a comparable application by sales and service partner OP System during the project planning phase. "At that time, we took one of our operators along for the test drive because, after all, he has to feel comfortable in the machine to achieve the best results," Johan Stenström tells about the decision-making phase. With the Mastercab, Delta Terminal finally chose an exclusive version of a large-capacity port cab, with which the operator works at a viewing height of around 11 meters. It offers a clear advantage: the improved overview of the ship's hull means that materials can be loaded faster and with greater accuracy. For maximum precision in loading operations, an additional camera was installed on the stick, which transmits the handling situation in the hull directly to a screen inside the cab.

How to avoid damage to the vessel's structure?

Just as importantly, the Safety Boom Lift system helps the operator avoid damage to the vessel's structure. When material is picked up by the closing grab, the boom lifts automatically without any further action from the operator: the system proves to be especially useful when only a small amount of material remains inside the vessel and the grab could drag on the ship's hull.

"All in all, we opted for the SENNEBOGEN 870 E because it offers us the complete solution we had been looking for: Thanks to Green Hybrid recuperation technology, it consumes around a third less fuel than comparable solutions without an energy storage system. Our operators also work more efficiently and the machine is constructed in such a robust way ex works that even after three years it is as good as new on our quay."

Machine in use

Press images

Press images

Press images

Press images