Indonesian paper mill with 9 material handling machines

In the industrial city of Pangkalan Kerinci, Indonesia, Riau Andalan Pulp & Paper (RAPP), a company of the APRIL Group, operates one of Southeast Asia’s largest pulp and paper mills. To keep production running smoothly, the site depends on fast and continuous timber handling to meet its daily processing targets.

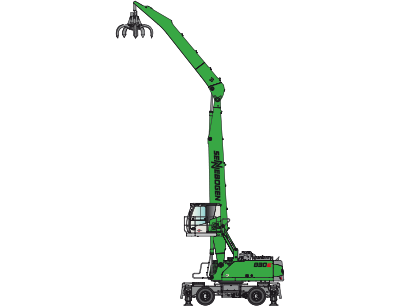

To meet these demanding requirements, RAPP chose SENNEBOGEN material handling machines. In April 2024, nine new SENNEBOGEN 830 E material handlers were commissioned. These machines were specially designed for handling large volumes of wood and are built to perform reliably even under high operating pressure. Timber handling is the backbone of RAPP’s operations: material is delivered from plantations, unloaded, sorted, and transported at high speed to the processing lines. Any delay in wood transport can directly impact production.

DESIGNED FOR TOUGH CONDITIONS

Local environmental conditions are extremely demanding. Indonesia’s hot and humid climate poses a major challenge, with temperatures ranging from 23 °C to 40 °C and humidity levels reaching up to 98 % year-round. RAPP also required a machine that could withstand dusty outdoor conditions while operating around the clock in three shifts. Many machines would struggle under these conditions, but the 830 E is built for exactly this kind of environment. Its efficient cooling system, reversible fan, and easily accessible service points ensure reliable operation day after day without overheating or clogging.

270 tons of wood per day per machine

Each machine handles up to 270 tons of wood per day and effortlessly lifts and places large timber bundles using the robust Rotobec grapple. Thanks to smooth hydraulic controls and a well-balanced counterweight system, the 830 E delivers precise stacking and placement — even at full boom reach. Its 13-meter reach allows operators to access high stacks and deep loading areas without repositioning, streamlining every task from unloading to stacking.

Fuel efficiency: just 19 liters of diesel per hour

Fuel efficiency is another major advantage: just 19 liters of diesel per hour. With nine machines in operation, this results in substantial long-term cost savings and reduced emissions. Unlike stationary machines or crawler units, all SENNEBOGEN 830 E machines at RAPP are mounted on mobile undercarriages. This allows them to cover large yard areas and be easily repositioned without low loaders or tractors. On-demand mobility supports RAPP’s flexible loading schedules and improves response time when yard requirements change.

Valued by the Professionals

One of the most experienced operators on site is Mr. Arnaldo, who brings over 20 years of heavy-equipment experience. For him, the SENNEBOGEN 830 E stands out not only for its power, but also for its comfort and control. He particularly appreciates the height-adjustable Maxcab cab, which offers an outstanding all-round view from a height of around 5.8 meters, as well as the intuitive control system that allows the 830 E to be operated with both strength and precision.

“The cab remains quiet and comfortable even after hours of work,” says Mr. Arnaldo. Another outstanding feature? The air conditioning. “Especially in our humid Indonesian climate, I really appreciate the cool air, which allows me to stay comfortable and focused”, he adds.

Reliable Long-Term Partner

From the outset, RAPP needed a machine partner that could provide not only equipment, but also a long-term material handling solution. SENNEBOGEN has delivered on this promise by combining high throughput, low fuel consumption, and easy operation with strong customer support. Since April, the entire fleet has been operating reliably, and RAPP’s operations team reports a significant improvement in efficiency in the wood yard — with operators like Mr. Arnaldo fully convinced. “These machines are fast, easy to control, and built for this kind of work”, says Mr. Arnaldo. “They have really made a difference.”

Machine in use

Press images

Press images

Press images

Press images

Press images