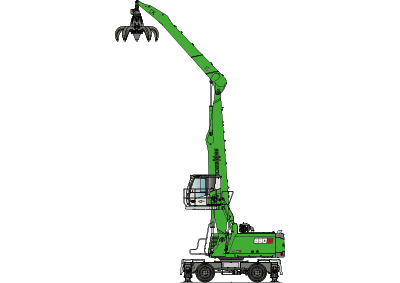

Material handler made of green steel for scrap recycling

Sustainable material handling and high performance are not mutually exclusive – on the contrary: at DEUMU's steel scrap recycling facility in Salzgitter, the SENNEBOGEN 830 G impressively demonstrates how CO₂ reduction and efficiency work together in practice. The 40-ton material handler, made from CO₂-reduced “green steel,” operates on a 40-hectare scrap yard with trimodal connections. There, it performs a wide range of tasks in the recycling process – from unloading ships to loading rail cars and trucks. Through the use of CO₂-reduced steel and low-emission operation, this handling machine contributes to a significant reduction in CO₂ emissions.

Circular economy in steel recycling: DEUMU relies on sustainable material handlers

Deutsche Erz- und Metall-Union GmbH (DEUMU) was founded in 1941 and has been securing the supply of raw materials to the steel industry for decades. As a subsidiary of Salzgitter AG, DEUMU consistently pursues the goal of decarbonizing the steel industry. A key component of this is the use of modern SENNEBOGEN material handlers, which themselves make an active contribution to CO₂ reduction, resource conservation, and the circular economy.

Jobsite Video

Green steel material handler: Sustainability throughout the entire product life cycle

The steel for the material handler comes from the Salzgitter Group's electric arc furnace route. By using recycled scrap and 100 % green electricity, over 70% CO2 is saved compared to steel produced conventionally in a blast furnace.

DEUMU supplied steel components for the new SENNEBOGEN 830 G made from precisely this green steel. In its subsequent use, the machine will again be used for steel scrap handling – thus consistently closing the material cycle.

Uwe Rehren, Managing Director of DEUMU, emphasizes: "We deliberately use CO₂-reduced products at our scrap yard, as the Salzgitter Group explicitly wants to play a pioneering role in this area. The new recycling excavator is part of the latest generation of SENNEBOGEN machines and operates around 20 % more efficiently than its predecessor. This saves an additional 18.5 tons of CO₂ per year during operation."

Versatile recycling machine for trimodal scrap logistics

The 40-ton SENNEBOGEN 830 G material handler with a 17-meter reach is used flexibly on the DEUMU site wherever high handling capacities are required. Typical areas of application are:

| Unloading ships | in the raw material area (up to 650 tons of scrap in 1.5 days, loaded directly onto trucks) |

| Loading | of finished scrap onto the rail |

| Handling | of new scrap and sheet metal waste |

| Feeding | of shredder feedstock (e.g. end-of-life vehicles) into plants |

The machine runs 365 days a year in 3-shift operation and covers long distances due to the large area. An integrated contamination measuring system on the grab ensures safety by detecting and excluding radioactive materials at an early stage.

Machine operator Johannes Hasler praises the new machine control system: “The SENNEBOGEN 830 G is very comfortable to operate. The intuitive touch display and the programmable operator profiles make everyday work much easier – especially with so many different areas of application.”

Long-standing partnership with service partner Schlüter

Since 2003, DEUMU has relied on SENNEBOGEN material handlers and the services of its sales and service partner Schlüter Baumaschinen. Marko Klickermann, division manager at DEUMU, explains: “The SENNEBOGEN 830 is our bread-and-butter machine. It has to be versatile – for filling rail cars, loading trucks, sorting, and feeding plants. Larger machines would have been too bulky, smaller ones would not have had enough reach. SENNEBOGEN has been delivering consistently high quality for years and is continuously developing its machines further.” The material handler made of CO₂-reduced steel is a deliberate, strategic and symbolic step for DEUMU. The aim was to make the circular economy a tangible reality – not just as a concept, but in real industrial use. At the same time, the technical feasibility of green steel was to be demonstrated and a genuine product innovation created.

“SENNEBOGEN is the right partner for this because there is trust and mutual supply relationships. This meant that the project could be implemented quickly, openly, and without lengthy coordination processes. For us, it's not just the product that counts, but the overall package. If a machine breaks down, we need a solution within a few hours – not after a long administrative process. This has been working excellently for years with SENNEBOGEN and its service partner Schlüter.”

Machines in use

Press images

Press images

Press images

Press images

Press images