Cranes are being replaced by material handling machine

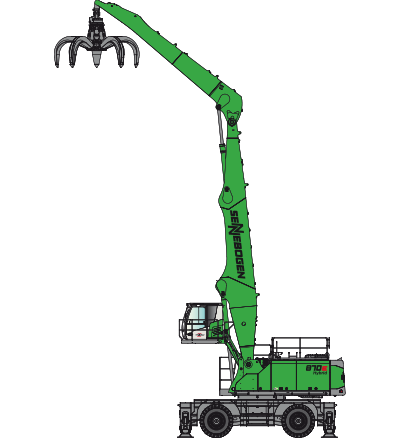

The long-established logistics company Albert Bergschneider, specialized in building materials, is investing in state-of-the-art handling technology: At the port location in Ibbenbüren-Uffeln, a new electrically powered SENNEBOGEN 870 E on rail gantry has recently been commissioned. The powerful material handler replaces two older installations – a rope gantry crane and an additional crane system – and now handles the bulk material transfer between inland vessel and freight train.

Specialist in trimodal logistics

With over 125 years of experience in logistics and building materials trade, the family-run company is now a regional expert in trimodal logistics between ship, rail, and truck.

From its five inland port locations along the Mittelland Canal and Dortmund-Ems Canal, Bergschneider supplies building material dealers and manufacturers across northwestern Germany. Two of these locations have direct rail access, ensuring efficient transport by train.

New machine replaces two older crane systems

At the Ibbenbüren-Uffeln site, located directly on the Mittelland Canal – Germany’s longest artificial waterway – the new machine was installed along a 340-meter-long quay with an adjacent storage hall and rail connection. The SENNEBOGEN 870 E on rail gantry is now responsible for bulk material loading and unloading between inland vessels and freight wagons, gradually replacing two older crane systems. The procurement and commissioning process was supported by SENNEBOGEN sales and service partner Schlüter Baumaschinen.

Shorter turnaround times and reduced operating costs

In Ibbenbüren-Uffeln, the SENNEBOGEN 870 E combines a 25-meter reach, a lifting capacity of up to 25 tons, and faster slewing movements – significantly speeding up vessel handling. “We were able to reduce the unloading time of a ship from five and a half to just two and a half hours,” emphasizes Managing Director Silva Haselon. The powerful 250 kW electric motor operates locally emission-free and with minimal noise. An integrated cable reel supplies the machine with power, ensuring flexible movement along the full 340-meter quay length.

In addition, the SENNEBOGEN Green Hybrid energy recovery system reduces operating costs by up to 30% compared to a conventional material handling machine. By using this innovative technology, Bergschneider avoids around 6.5 tons of CO₂ emissions per year at the site.

Powerful and sustainable port logistics

The spacious Mastercab, equipped with hydraulic height adjustment, offers a variable working height between 8 and 12 meters. Thanks to the elevated cab position and additional camera systems, the operator benefits from excellent visibility of the entire working area.

With the new SENNEBOGEN 870 E, Bergschneider is investing in a powerful and environmentally friendly material handling solution: Two outdated systems were replaced, handling times and operating costs significantly reduced, and CO₂ emissions lowered – an important step toward efficient and sustainable port logistics.

Machine in use

Press images

Press images

Press images

Press images