Grain handling in cargo port

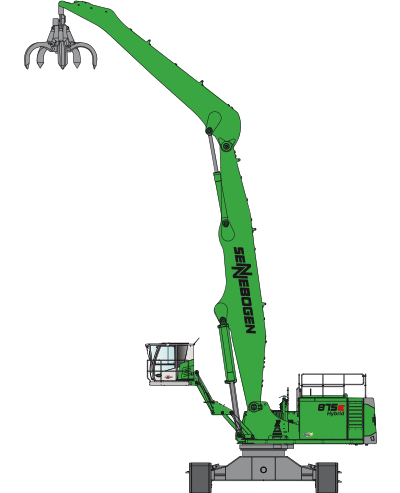

The PK Terminal in the Estonian port of Muuga is one of the most modern cargo terminals in Europe. Since 2019, the company has been relying on high-performance SENNEBOGEN material handlers: two 875 E, one 870 E and one 355 E to efficiently handle bulk goods and steel. With the purchase of an 885 G in this year, the PK Terminal is confirming its long-term focus on the proven technology and efficiency of SENNEBOGEN.

Cargo port with over 50 years of experience

The PK Terminal, operated by the Palgard Group, can look back on over 50 years of experience in port handling. At the Muuga site, Estonia's largest freight habour, the company operates two quays where up to three ships can be handled simultaneously. The main goods handled are grain, wood pellets and steel products. Thanks to its excellent road and rail connections, the freight terminal is an important hub in the European transit trade. Muuga is particularly important for grain exports to Africa, the Middle East and Europe.

Jobsite Video

Reduced berthing time for grain handling

The terminal uses two SENNEBOGEN 875 E material handlers to load grain onto Panamax ships. Equipped with 12 m³ grabs, these machines achieve an impressive handling capacity of 600 tonnes per hour each. This shortens the lay times of the ships considerably. Despite the high handling capacity, the SENNEBOGEN Green Hybrid energy recovery system ensures low consumption - making operation particularly economical and environmentally friendly:

“The decision was made in favour of a machine that enables maximum efficiency at a reasonable cost. SENNEBOGEN machines are extremely powerful, and the hybrid system also ensures low fuel consumption.“ Rain Rannala, Board Member PK Terminal.

Excellent view into the ship's hull

The advantages of the two SENNEBOGEN 875 E machines become especially evident during the loading of Panamax ships. The crawler portal combined with the Portcab cabin, featuring Skylift height adjustment, provides optimal visibility into the ship's hull.At the same time, the innovative SENcon control technology ensures precise operation at high handling speeds. Board member Rannala emphasises that operators also highly value these features: "Our operators particularly appreciate how easy the machines are to handle, enabling them to work with great precision despite demanding tasks."

Cargo terminal expands SENNEBOGEN fleet

In order to meet the increasing demands in the port of Muuga, the PK Terminal will expand its fleet of machines with a SENNEBOGEN 885 G. This investment is expected to further enhance the terminal’s ability to handle larger ships more efficiently.

With this fleet expansion, PK Terminal reaffirms its trust in SENNEBOGEN’s solutions: powerful, efficient, and environmentally friendly machines that meet the challenges of modern port operations.