Versatile and reliable: Premiere for the new 100 t duty cycle crane for Van 't Hek

The company Gebr. Van 't Hek B.V. recently started to operate with one of the first new SENNEBOGEN 6100 E duty cycle cranes. A real premiere in the Netherlands! The all-rounder for demanding applications was delivered by sales and service partner Van den Heuvel.

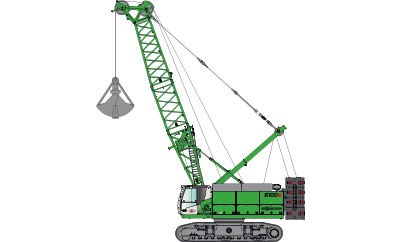

Move Big Things – The new duty cycle crane class

The new SENNEBOGEN 6100 E, a duty cycle crane in the current E series, has been designed with challenging, dynamic applications in mind. His first job took the 100 tonne duty cycle crane to Rhoon in the Netherlands, where it was used by Van 't Hek for a wide range of lifting and foundation work. Here it is helping to install 105 HEK-combi-piles, each 33.5 metres long and with a weight of 12.3 tonnes each, as foundations for the new town hall of the municipality of Albrandswaard As an auxiliary crane, it will perform important tasks within the entire foundation work. The duty cycle crane will be lifting the formwork for the drilling, inserting the Octicon® prefabricated piles used on this construction site into the borehole and filling it with mortar using a bucket. The trend in civil engineering is clear: longer and longer piles and sheet piles are being used, the piling equipment is becoming significantly heavier: the SENNEBOGEN 6100 E is already up to these future challenges today.

Individually configurable according to customer requirements

Available ex works in the Heavy Duty version and with a wide range of equipment options, the SENNEBOGEN 6100 E can be individually configured to customer requirements. At Van 't Hek, it is used as a crane, but also for dragline bucket applications, for grab work or as a casing machine with leader. The big advantage of this HD crawler crane is that it has extra hydraulics and has more hydraulic power than a "standard" 100 t crane. In this way it is possible to work without an additional power pack, and the crane itself supplies the hydraulic hammer with the necessary oil flow.

Easy to transport

With the crawler tracks fully extended, the 6100 E has a width of 5 metres, offering outstanding stability. For transport, the undercarriage can be retracted to 3.5 metres and the transport weight reduced to less than 41 tonnes. The duty cycle crane can assemble itself without an auxiliary crane, this also applies to the self-assembly system of the ballast: The 6100 E can pick up and set down its own ballast.

Crane operator enthusiastic about safety, comfort and ergonomics

Crane operator Marc Mulder is very pleased with the new crawler crane, especially the comfort of the Maxcab cabin, the operation and the safety were completely convincing. He has to get out of the cab regularly to assist in this project - the good accessibility via many steps offers great added value, a circumferential upper carriage railing as well as numerous catwalk options provide maximum safety for the driver and operator. Van 't Hek and its customers attach great importance to this. Additional headlights have been fitted and additional railings have been added to the upper carriage. Side steps on the crawler tracks allow safe access to the Maxcab, which can be tilted 20° and has a safety guard. The window is made of special bullet-proof glass, one of the many options Van 't Hek has chosen.

Strong performance, strong appearance

Fittet with a 52.3 m lattice boom and a 451 kW 6-cylinder engine, the 100 t duty cycle crane of course meets the stage V emission standards. The engine is equipped with an auto-stop function and switches off automatically when it is idling for a defined period of time, which saves fuel. The large pumps provide high hydraulic power, so that the duty cycle crane can operate a vibrator or pile driver itself. For this purpose, hydraulic lines are laid up to the distributor at the front of the crane. If the hydraulic power needs to be increased, an optional extra hydraulic system can be supplied that provides an additional 420 l/min. The 6100 E is equipped with two 16 t main winches and a third winch with 11 t pulling force.

The new 100 t SENNEBOGEN duty cycle crane can play to all its strengths on the first project in Rhoon and is convincing all along the line in its Dutch baptism of fire.

Machine in use

Press images

Press images

Press images

Press images

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_SENNEBOGEN-355-telescopic_handler-recycling_industry__2__3ce0081c3b.jpg)