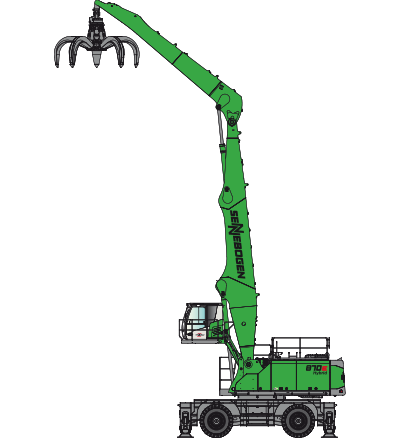

Port material handling with SENNEBOGEN 870 in Belgium: DD Shipping NV unloads steel wire coils safely and efficiently

DD Shipping NV, member of the Square Group, is a stevedoring company for dry bulk goods and general cargo. The company runs two terminals along the Brussels-Scheldt Maritime Canal – one of the most important inland shipping routes in Belgium. For more flexibility on their two quays, the material handling experts at DD Shipping NV have invested in a stable crawler gantry solution: the efficient SENNEBOGEN 870 Hybrid E series ensures fast and easy loading and unloading of heavy cargo and bulk material.

DD Shipping NV in Puurs is located at the sea lock of Wintam and thus benefits from the ideal location between Antwerp and Brussels. The sea lock in Wintam is 8.80 m deep, 250 m long and 25 m wide: as a result, ships with a capacity of up to 10,000 tons can pass through it and dock at the quay of DD Shipping. Only recently a second quay was opened at the port specialists' premises, which will shortly also go into operation.

"We decided on a maneuverable version of the material handler so that we can use it flexibly on both quays in the future," reports Geert Keeris, Managing Director of DD Shipping, on the investment and strategic reorganization of the company in collaboration with sales and service partner SMT Belgium. Several factors were decisive when purchasing the new material handler: "With the SENNEBOGEN 870 E we now have a stable, mobile machine with a large handling capacity, which is both comfortable and ergonomically designed for the driver".

Port logistics made easy with crawler gantry and purpose-built equipment

With a clearance height of around 5 m, trucks can easily pass underneath the machine and then be loaded, which saves a lot of time. As a result, storage spaces are not occupied unnecessarily, berthing times of the ships are drastically reduced, and intermediate transports are now a thing of the past. From the cab, which can be raised by 7 m, the operator always enjoys unrestricted visibility. An additional camera mounted on the stick and the respective monitor in the cab help the operator to precisely pick up the material even inside the ship's hull.

If required, SENNEBOGEN can equip all port material handlers with a special equipment configuration in order to achieve even higher handling capacities: The special 25 m port equipment, which is also used by DD Shipping, is made of robust, high-strength steel, which enables particularly light-weight constructions and at the same time more load capacity due to the weight savings. As the Belgian port specialists have to process different types of material, the special configuration pays off especially when loading heavy break-bulk: "Our ship today contains 2,162 steel wire coils. At peak times, we unload up to 160 coils per hour with our SENNEBOGEN," reports Geert Keeris about the operation performed.

BIG energy savings thanks to the SENNEBOGEN Green Hybrid System

"In this demanding work environment, it is important for us to save energy in the process – one of the main reasons why we chose the SENNEBOGEN 870 Hybrid. We are simply trying to follow a 'green' line," Geert Keeris continues. DD Shipping is now supported in this endeavor by SENNEBOGEN's Green Hybrid system, the most advanced recuperation technology on the market: an energy storage module consisting of nitrogen and piston accumulators is located in the secure, enclosed rear area of the machine. There, gas is compressed when the boom is lowered. At this point, the ability of the gas to be compressed is utilized and energy is temporarily stored, which is available again during the next stroke. The so-called hydro-pneumatic accumulator principle works similarly to a spring that is compressed and releases its energy when it moves back to its initial position: The resulting power output compensates for the mass of the boom and raises it without requiring any further energy input. Depending on the task to be performed and if the system is correctly preloaded, the Green Hybrid module can save up to 50% energy – a major advantage in the highly competitive port business.