Modern green waste recycling at disposal specialist Hahn

For Wolfgang Hahn everything is about green. The entrepreneur from Pfatter near Regensburg has made a name for himself in the region with his company "Hahn Kompost". Recycling is a way of life here: tons of wood, green waste and other recycling materials arrive here daily, are sorted, shredded, processed or composted and often end up back in the farmer's field or in the garden bed of the end consumer. An almost infinite cycle, it seems. The Hahn employees ensure that this cycle also runs continuously with the help of impressive machinery. This includes three SENNEBOGEN machines, from the small 355 E telehandler to the 825 E material handler.

"From nature - back to nature" is how founder and owner Wolfgang Hahn describes the recycling concept of his company, founded in 1993 in Pfatter near Regensburg. As a compost and waste management company, the company is in the middle of a functioning cycle. The material, which is delivered daily, ranges from green waste cuttings from the surrounding communities and towns, construction and demolition wood as well as damaged wood from forestry, to wood from the Danube and Isar rivers. That is taken by Hahn on behalf of the river maintenance authorities at the hydroelectric power plants and further utilized.

constant view of the work area for the driver

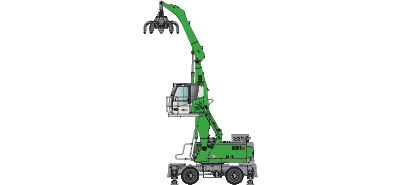

Almost everything then ends up in the shredder or crusher to prepare it for further processing. This is where the SENNEBOGEN material handlers are used. While the SENNEBOGEN 821 E is mainly responsible for feeding the Doppstadt shredder with waste wood, the 825 E is responsible for feeding the shaft shredder. In the midst of meter-high heaps of material, the machine with its 13 m equipment and orange peel grab constantly shovels green waste, branches and root wood onto the shredder. Thanks to the 2.70 m elevating Maxcab cab, the driver not only has a constant view of the work area around him, but can also conveniently monitor the fill levels of the shredders. The screened material is later transported to be composted. Here the new SENNEBOGEN telehandler 355 E is used. Equipped with a 3.0 m³ loading shovel, the newcomer has quickly established itself as a flexible all-rounder. No matter whether for material transport, feeding the drum screen or loading onto trucks, the 355 E competes with even the large wheel loaders thanks to its elevating cab and unique eye level of 4.25 m. SENNEBOGEN Vertriebs GmbH, based in Straubing, Germany, takes care of regular service and spare parts supply and is quickly on site if necessary.

telehandler with a lifting height of up to 8.5 m

Especially the new telehandler with a lifting height of up to 8.5 m and a maximum load capacity of up to 5.5 t once again puts the special features of SENNEBOGEN machines in the foreground. Because the 355 E is more than just a classic telescopic loader. Thanks to the wheel loader genes including Z-kinematics, a particularly robust steel construction and the design of all components for demanding continuous operation, the smallest representative of the SENNEBOGEN product portfolio is in no way inferior to the larger machines in terms of reliability, service friendliness and comfort.

Every year Hahn produces, transports and processes around 150,000 m³ of wood chips, 20,000 t of waste wood and also 15,000 t of grate and boiler ash. The latter is produced during the thermal utilization of the wood waste and can be added to the compost as fertilizer to improve the material. "We are thus closing the cycle," says Wolfgang Hahn. Regardless of whether it's compost, bark mulch or plant soil, in the end almost everything ends up back at the customer.

Jobsite Video

Machines in use

Press images

Press images

Press images

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_SENNEBOGEN-355-telescopic_handler-recycling_industry__2__9aa89e9cf6.jpg)