Timber handling solutions from SENNEBOGEN: Full line working at New Zealands Pedersen Group

The introduction of four key SENNEBOGEN material handling machines at one of the world’s largest pulp and paper facilities has helped create a substantially more efficient operation for services provider Pedersen Group. The range of log handling hardware Pedersen implemented at their Tasman Mill operation is truly comprehensive; encompassing both the smallest, the SENNEBOGEN 818, and the largest materials handlers, the SENNEBOGEN 880 EQ.

Pedersen Group provides for a vital production link in terms of log yard logistics, mobile plant operations and whole log chipping and debarking services at the Tasman Mill, which operates on a 200ha site near the Bay of Plenty town of Kawerau in New Zealand’s North Island. The mill site hosts pulp production operations for both CHH Pulp & Paper and Norske Skog. The Pedersen Group team handles log volumes of 1.1m tonnes per annum, undertaken on a seven day, double shift operation.

"Not only was the decision to move to SENNEBOGEN mobile plant based around the relative technical abilities and robustness of the individual machines, but utilising the advanced capabilities of SENNEBOGEN allowed us to change the way we use both our fixed and mobile plant and led to us reconfiguring our entire yard for maximum efficiency”, says Pedersen’s Kawerau Site Manager Marty Hine.

Electrically driven SENNEBOGEN 818 as comfortable control center

At the smaller end of the scale, a static, electric drive SENNEBOGEN 818 acts as the control centre for the debarking drum and conveyor feed into the 3000hp multi-log chipper. In almost every other facet though, the 818 is an off-the-shelf electric powered materials handler, simply sited for maximum efficiency.

“The hydraulic elevating cab raises and lowers in a conventional manner so the operator has excellent vision of what’s coming from the power infeed, through the debarker and down the conveyor in front of him,” says Marty.

“Essentially the 818 is the nerve centre for the whole plant, with the operator using touchscreen and joystick controls in the oversized cab to control product flow at variable speeds and deal with jams using the 818’s grapple.”

SENNEBOGEN 880 EQ – Equilibrium Handler offering enormous working radius

The electric drive SENNEBOGEN 880 EQ is one of the world’s largest materials handling machines. Pedersen’s unit weighs in at 275,000kg with a 5 m pylon, 30 m boom and impressive 11 m operator eye level; it is the largest machine of its type in the Southern Hemisphere. While offering all the efficiency benefits of electric power, the machine is still mobile as it sits on crawler tracks in order to travel up to 35m.

Marty says he is impressed with the precision of the SENNEBOGEN 880 EQ, citing the balance the machine exhibits, regardless of load, as exceptional. Even at the 880 EQ’s full reach (30 m) and with total weight in the grab of 12 ton, the machine is never in danger of toppling over. This is due to SENNEBOGEN Equilibrium design, with a moving counterweight to help keep the load centred. The long reach SENNEBOGEN 880 EQ can unload from the trailers straight into the power infeed, or across to the store.

Towing up to 60 t – SENNEBOGEN 830 Trailer improving log yard logistics

Alongside the supersized handling capacities of the SENNEBOGEN 880 EQ are two mid-range log handlers – twin SENNEBOGEN 830 MTs – which have also proven real game-changers for Pedersen Group at Kawerau. The 830 MT is the only materials handler/log handling machine that can tow 60 ton of logs.

“Before the SENNEBOGEN 830s arrived we were using wheel loaders, which can’t stack as high as the 830s can. Wheel loaders can’t tow either, so we’re moving more logs and stacking them more efficiently with a bookend system. The way we use space within the yard has improved dramatically as a result,” says Bruce.

“This reconfiguration also eliminates our old log deck and waterfall system, which means the wood is handled less. As a result there’s less damage and loss of fibre on the product being processed,” says Project lead Bruce Hutchins.

Marty Hine says SENNEBOGEN parts and technical support from Australasian distributor Pacific Materials Handling (PMH) has been fantastic.

“PMH have really been with us every step of the way on this. Couple this support with better running costs, cheaper consumables and parts and less in the way of service costs and we’re ahead across the board."

Pacific Materials Handling SENNEBOGEN Business Manager, Byron Judd echoes these sentiments: “From the initial phone call onwards, developing this plan alongside the Pedersen Group team has been a truly rewarding working partnership.

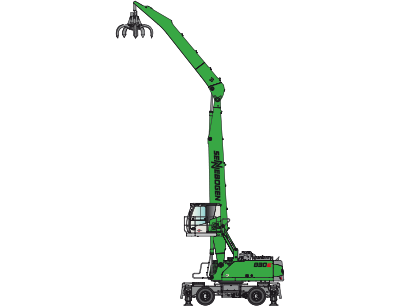

Caption:

A total of four SENNEBOGEN material handlers, including two with a trailer, are working for Pedersen Group in the Australian Tasman sawmill. From the smallest SENNEBOGEN Model, the 818 to the largest of machines, the 880 EQ, the entire bandwidth is used.

Machines in use

Press images

Press images

Press images

Press images

Press images