SENNEBOGEN cranes for 1500 mm diaphragm walls in Paris

Special civil engineering work for the future Grand Paris Express underground network is in full swing. On Line 15 West, teams from NGE FONDATIONS are working on several construction sites simultaneously, using multiple SENNEBOGEN cranes and duty cycle cranes for both foundation and lifting work.

Grand Paris Express infrastructure project

The Grand Paris Express is a new underground transport network for the Greater Paris area, which has been under construction since 2016 and is scheduled for completion in the early 2030s. The infrastructure project is one of the largest currently underway in Europe and comprises six fully automated metro lines that will expand the existing Paris metro system, including 68 stations and seven technical centers. A new, sustainably designed network of lines is being created, which is primarily intended to significantly improve connections and exchanges between the surrounding communities. Once completed, the new Line 15 West will be the longest metro line in France and, as a bypass route around the city center, will cross a total of 45 municipalities and four departments in the Île-de-France region.

Together with general contractor Webuild and French engineering services provider Equans France, French civil engineering company NGE Fondations, as a group, was given the fourth and final government contract for the design and construction of the western section of Line 15 at the end of May. The project is worth €1.38 billion and is scheduled for completion by the end of 2031. This final section will ultimately complete Line 15. It will connect Bécon-les-Bruyères station with Saint-Denis - Pleyel station and includes 7 km of tunnels, 4 new stations with connections to the existing network, and major building blocks (apartments, offices, shops, etc.).

Two specialized civil engineering projects in Gennevilliers: service tunnel and subway station

A few months ago, NGE FONDATIONS teams began work on the diaphragm walls to create the foundations for the first two construction projects of the consortium led by NGE:

This concerns, on the one hand, the “Les Caboeufs” service tunnel in the municipality of Gennevilliers. This site will be the entrance shaft or service structure for the tunnel boring machine, which will drill a 7.5 km long tunnel. The special feature of this construction phase is the tunnel boring machine's operating method, which works in two consecutive steps. A first section of 1.2 km will be built in an easterly direction to Saint Ouen, and a second section will then connect to the “Bécon les Bruyères” business district in the direction of Courbevoie / La Défense.

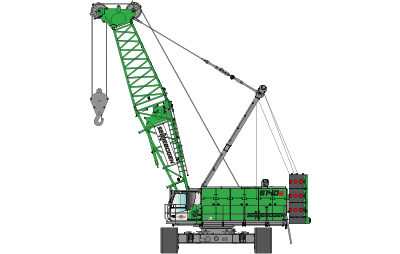

Foundation work: 1200 mm thick diaphragm walls constructed

In preparation for the upcoming tunnel boring, NGE FONDATIONS is constructing the 1200 mm thick diaphragm walls. This is being carried out using a SENNEBOGEN 6130HD duty cycle crane with a STEIN diaphragm wall grab and a hydro cutter. The diaphragm wall elements are 50 m deep, with the outer walls measuring 1,000 mm and the central partition wall measuring 1,200 mm in thickness. Two closure plates – one at each end – complete the structure and act as shielding in both directions, preventing any major water leakage that may be generated by the tunnel boring machine.

Heavy-duty lifting with crawler cranes and duty cycle cranes

The lifting work required, particularly that involving the reinforcement cages, is being carried out using a SENNEBOGEN 3300 crawler crane with a lifting capacity of 125 tons, which was provided by FORCE-LOC. Equipped with a main winch and an auxiliary winch, the crane ensures that the steel mesh is lifted safely so that the welded metal structures remain undamaged. The heavy-duty lifting work is carried out by the 140-ton SENNEBOGEN 6140 HD duty cycle crane, which is also used on the construction site. Equipped with two 350 kN free-fall winches, it will also be used in civil engineering work on the next construction site of the Gare des Agnettes railway station from the beginning of 2026 with a 1500 mm diaphragm wall grab.

A variety of civil engineering work for the duty cycle cranes

Ninos Salur, civil engineer for the service building, explains: "The SENNEBOGEN cranes and duty cycle cranes proved to be very efficient both during lifting and foundation work. We will also be using the duty cycle cranes again at the next construction site at Les Agnettes station, using the 6130HD for heavy-duty lifting and the 6140HD for constructing the diaphragm walls. The diaphragm walls at this station will even be 1500 mm wide. We greatly appreciate the technical support provided by the SYGMAT teams and their help in setting up and dismantling the machines." Once the diaphragm walls have been completed, the construction company will hand over the project as planned to the earthmoving and civil engineering teams, who will excavate the material and create the actual construction pit so that the tunnel boring machine can be used from fall 2026.

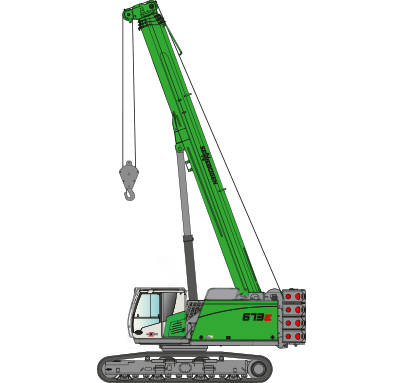

Telescopic crawler crane 673 E: Flexibility on difficult terrain

The second construction project in Gennevilliers is the future Les Grésillons station. This will be the first construction site that the tunnel boring machine will pass through as it advances westward at a depth of 27 m. The dimensions of the excavation pit in which the future station will be built are 25 x 108 m.

The most delicate technical challenge in constructing these foundations lies in the immediate proximity to the existing RER C railway line. This is because Les Grésillons station will become the junction for the railway line and will carry around 60,000 passengers a day. Another complexity arises from the proximity to the Seine River. This makes the subsoil somewhat unstable, requiring exceptionally thick walls to support the structure, i.e., the walls must be up to 67 m deep and 1500 mm thick.

On this construction site, the civil engineering work is being carried out by two carrier machines with diaphragm wall grabs and hydro cutters, while the heavy lifting is being handled by a crawler crane. All other lifting and loading work is carried out by the SENNEBOGEN 673 E telescopic crawler crane with a lifting capacity of 70 t. The all-terrain telescopic crane was chosen for its compactness and versatility. “It enables us to meet a wide range of requirements on the construction site during all phases of construction: preparation of reinforcement cages, concreting work, and all fast loading work throughout the construction site. Its ability to move under load and freely adjust its boom length even under load are real advantages for our teams,” explains civil engineer Loris Berniot.

Machines in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images