Port Handling: Diesel or Electric Material Handlers?

In the industrial heart of the Aegean region, at İDÇ Liman port just two kilometers from the company’s own steel plant, thousands of tons of coal, scrap, iron ore and other bulk materials pass over the quay every single day. With an annual throughput of 7.5 million tons, a quay length of 475 meters and the capability to handle vessels up to 120,000 DWT, efficiency here is not an objective – it is an absolute necessity.

Steel producer operates one of Turkey’s most important ports

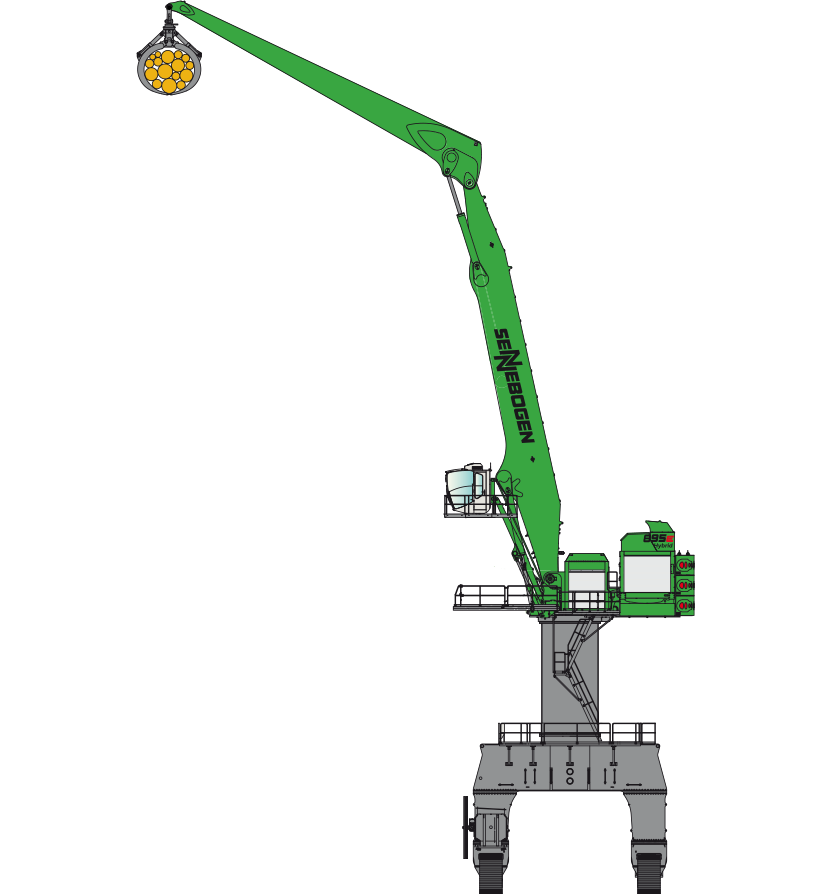

The publicly listed company İzmir Demir Çelik Sanayi A.Ş. is among Turkey’s most respected steel producers and operates one of the country’s most important ports at the strategically located Aliağa/Izmir axis on the Mediterranean. To ensure reliable port handling operations, İDÇ Liman operates ten SENNEBOGEN machines, including four 880 EQ Balancers, two 895 E material handlers, one 9300 harbor mobile crane and several other harbor cranes.

The world’s largest material handler at İDÇ Liman port

High handling volumes require powerful machines. The heart of İDÇ Liman consists of two SENNEBOGEN 895 E material handlers with crawler portal undercarriages, which fully demonstrate their strengths on site:

| 40-meter reach | Handling especially large vessels |

| Robust design | Reliable continuous operation |

| High load capacities | Outstanding handling performance |

| Green Hybrid energy recovery system | Reduces operating costs by up to 50 % |

| Electric drive | Maximum energy efficiency |

Electric or diesel drives for material handlers?

Hardly any other location in Turkey can answer the question “Diesel or electric material handlers?” as well as İDÇ Liman. For many years, the port has consistently relied on electric drives – for three key reasons:

Up to 80 % lower operating costs

The port has been relying on electric drives for new machines for several years now. In addition, diesel-powered material handlers are increasingly being converted to electric operation. The savings potential of such a conversion is clearly demonstrated by an 880 EQ in operation at the port:

“We reduced our energy costs by up to 80 % after converting the machine from diesel to electric, without any loss in performance”, reports port manager Emre Söyler.

Higher availability

Compared to diesel-powered machines, electric port material handlers offer significantly extended service intervals, fewer wear parts and eliminate time-consuming refueling processes.

Long service life

Electric motors prove their strengths in port applications thanks to their simple design. Unlike diesel internal combustion engines, they feature far fewer wear-intensive components such as pistons, plain bearings or complex injection systems. As a result, electric motors are less prone to costly and time-consuming repairs.

More than 50,000 operating hours

The long service life of SENNEBOGEN material handlers is impressively demonstrated by an 880 EQ Balancer at İDÇ Liman.

In addition to the robust machine technology, SENNEBOGEN’s service and sales partner Forsen Makina is a key factor in ensuring high availability:

“We don’t just sell machines. We provide lifetime support – spare parts, maintenance, training, everything. At İDÇ, we have built a relationship that has lasted for 20 years. It’s not just about machines, it’s about trust.” - Emin Gök, Forsen Makina

Machines in use

Press images

Press images

Press images

Press images

Press images

Press images