SENNEBOGEN 130 t telescopic crawler crane proves its worth in the assembly of concrete parts for the major new VGP Park project in Munich

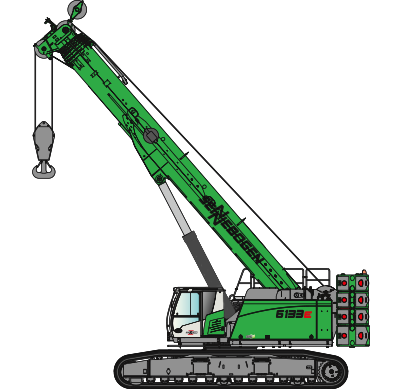

60,000 m² production area, 2,700 elements to be lifted, 20,000 m² ceiling systems - with the new construction of the VGP Park in Munich, Karl Bachl GmbH & Co. KG was awarded the contract for a challenging large-scale project. On an area of almost 700,000 m², almost 400,000 m² of logistics, production and office space will be built at the northern Parsdorf junction of the A 94 freeway, for the BMW Group and the KraussMaffei Group, among others. In bright red, a new SENNEBOGEN 6133 E is operating in its baptism of fire here. Since June 2020, it complements the Bachl fleet with a 130 t telescopic crawler crane.

In search of a replacement for a 100 t mobile crane with 22,000 operating hours, Bachl decided to invest in a new crane in 2019. This was followed by extensive research regarding manufacturers and machine concepts. In the end, the choice was made for the SENNEBOGEN 130 t telescopic crawler crane 6133 E, which was able to fully convince with its concept advantages. This decision was prepared by Robert Blöchl (senior project manager) in cooperation with Andreas Schanzer and Wolfgang Hoffmann as well as SENNEBGOEN sales and service partner IBS Industrie- u Baumaschinen-Service GmbH.

"We were looking for a powerful crane that could move our components flexibly during the prefabricated assembly on the construction site. But it should also have compact dimensions, as we often have limited space on site. What was also important for us: that we could move the crane easily and cost-effectively from one construction site to the next. These points were all given with the 6133 E," says Robert Blöchl.

After handing over the crane in Straubing, its first deployment under crane operator Alfred Kempinger took it to the VGP Park construction site in Munich, where it has been passing its baptism of fire since the end of June. His work includes the assembly of the reinforced and prestressed concrete prefabricated parts. A construction period of seven months is planned for lifting a total of 2,700 elements and installing more than 20,000 m² of ceiling systems.

time pressure and large area - Telescopic crawler crane as perfect machine concept

The Karl Bachl GmbH & Co. KG is a specialist for interdisciplinary construction projects ranging from single-family homes to operational, administrative and production buildings, as well as logistics centers. Of course, this requires the ability to provide modern service competence, decades of know-how and a group of companies that is able to deliver everything from one hand.

Robert Blöchl comments: "For our precast construction division, this is the largest single contract we have ever handled, so the scale of the project and the volume in general is a challenge for us. The same applies to the floor space: the hall has over 60,000 m², so it was clear that we definitely needed a telescopic crawler crane in order to have as few moving operations as possible and to remain flexible. This in connection with the construction time - the assembly of the hall should be completed by mid-November 2020 - is the special challenge for us".

Thanks to Pick & Carry: Lifting and moving under load

The telescopic crawler crane will be used to build the halls. This mainly involves lifting and moving the columns, walls, intercepting beams, frost barriers and girders, the largest components at 32 m in length and weighing almost 35 t. The approx. 400 supports have up to 26 t and a length of approx. 18 m, so they are relatively large supports for a hall. The 6133 E has a maximum main boom length of 52 m due to its 6-section boom, with the optional 15 m fly jib even reach heights of up to 67 m are possible. Thanks to Pick & Carry, it can move under up to 100 % of the load and offers high stability and manoeuvrability thanks to its 5.40 m track width.

Robert Blöchl explains the special requirements a machine must meet for these tasks: "For jobs such as halls or logistics halls, the most important thing is to be flexible on the construction site, in other words, there is no way around a telescopic crawler crane. On the one hand because of the large area, on the other hand also for logistical reasons. If, for example, the delivery of certain components is delayed or the assembly sequence is changed, the 6133 E can be easily moved thanks to the crawler tracks, and in no time at all it is at another location where work can continue. Thus, a telescopic crawler crane is actually "indispensable" for such construction sites.

WOULD AN AT CRANE BE AN ALTERNATIVE HERE?

"No, it would be much slower and could never be used as efficiently and effectively as the telescopic crawler crane," says Lennart Stecher from sales and service partner IBS.

Robert Blöchl confirms: "We would choose this machine again at any time. Firstly, we are absolutely satisfied, and secondly, we have several projects where a telescopic crawler crane is ideal for use".

We are very pleased to move big things together with this customer!

Jobsite Video

Machine in use

Press images

Press images

Press images

Press images

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_SENNEBOGEN-355-telescopic_handler-recycling_industry__2__3ce0081c3b.jpg)