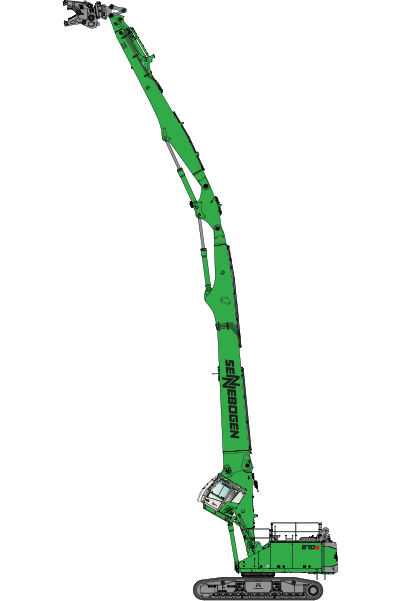

Steel hall has to be removed - a job for the SENNEBOGEN Longfront Demolition Material Handler 870 E

In the meantime, the Bavarian company Sauer Bau und Projektentwicklung GmbH has already successfully completed several demolition operations with its new SENNEBOGEN 870 E longfront demolition material handler. But every time it's something special when the green machine with its 33 m equipment length and 4 t payload starts working.

In the period from October to December 2018, a 16,000 m² steel construction hall built in 1920 in Nuremberg was demolished in a controlled manner. The task of the demolition handler was to grasp individual facade elements and entire building structures accurately and precisely with the demolition shears or grab and bring the components safely to the ground. At the same time, the machine can shred and load the material on site - thanks to the flexible change options between sorting grabs, concrete or scrap shears.

The driver, Martin Sturm, emphasizes the safety aspects of the demolition handler: "Thanks to the tiltable and elevatable cab, I have a good overview of my working area even when we have to operate on very high buildings, and at the same time I am protected from falling objects by safety grids on the roof and windshield."

According to Sturm, a further advantage for the work processes on the construction site is the simple commissioning of the demolition handler: Since the machine can be set up and dismantled by itself without external assistance, no additional auxiliary crane is required.

"The demolition in Nuremberg was now the fifth construction site that we have successfully completed since we purchased our 870. We are particularly pleased to always have a reliable service and contact partner at our side in IBS GmbH," says Florian Trinkl, Managing Director of Sauer Bau und Projektentwicklung GmbH.

Machine in use

Press images

Press images

Press images

Press images