Hydraulic engineering with 140 t duty cycle crane: Reconstruction of a quay

Directly after its journey across the Indian Ocean, the newly acquired SENNEBOGEN 6140 HD from ABC Maxilift went to its first jobsite. During the reconstruction of the Grand Port Maritime quay, the versatile duty cycle crane is performing lifting and loading operations as well as dynamic special civil engineering work with pile driver and drilling rig.

The Poste N°1 pier is located on the west side of the French overseas island of Reunion. It belongs to one of the largest fishing companies in the Indian Ocean, SAPMER, which operates its warehouses directly at the quay and also unloads its ships there. In the meantime, however, the port infrastructure, built in the 1950s, was showing clear signs of fatigue. In order to ensure the continued safety of operations and to protect the immediate marine environment, it was therefore decided to renew the quay.

Demanding construction site in hydraulic engineering

The demolition and subsequent reconstruction of the quay was entrusted to a consortium of two construction companies ROC and NGE Fondations, both subsidiaries of the NGE Group. Reconstruction began as early as May 2021, with plans to build a foundation structure resting on 40 driven piles and supporting a network of longitudinal beams, which will in turn support the bottom slab of the new quay. The new pier, built in this way over a length of almost 130 m, will allow a draught of up to 6.20 m and will be able to accommodate 90-meter-long ships weighing up to 2,700 tons.

Versatility due to heavy duty equipment

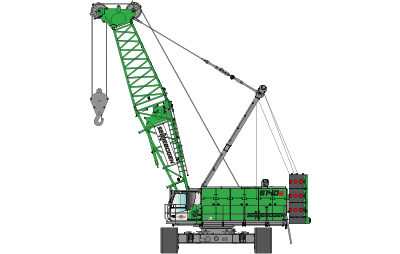

For a project of such dimensions, many different lifting operations are required. Therefore, a particularly versatile and powerful crane was needed. ABC Maxilift, one of the main players in the lifting industry on the island, was asked to provide a suitable solution for the specific requirements of this project. "The most challenging point on this site is the long distance of the driven piles from the pier. The SENNEBOGEN 6140 HD duty cycle crane with 35 m boom still lifts 17 t even at a radius of 24 m, and can therefore easily drive the outermost piles in the ground," says Nicolas Cheung-Ah-Seung, operations manager of the crane service provider. The machine's versatility was also a key criterion. Thus, the 6140 HD not only performs all kinds of lifting and loading activities on the construction site, but also the particularly heavy, dynamic work for which it is designed. Thanks to its heavy-duty design and its two winches, each with a pulling force of 350 kN, it takes over the vibration of the foundation tubes and controls the heavy Delmag pile driver. Equipped with a cable grab, it is also used on the construction site for excavating the material inside the drill pipes. A plus point of the duty cycle crane in this application is the programmable depth measurement device, and that the winches and are automatically synchronized. In addition, it also takes care of the casing work and shines here thanks to the use of its free-fall winches.

An investment that pays off: The powerful 140 t duty cycle crane

It was a good thing that ABC Maxilift decided to purchase a 140 t SENNEBOGEN duty cycle crane back in 2020, after SENNEBOGEN's French sales partner SYGMAT showed them the development opportunities that this powerful machine could open up for its business field. Thanks to this wise foresight, the company was also able to service this job at the port very quickly. The brand new 6140 E arrived on the island as early as May 2021 and went into operation immediately.

Jean Cheung-Ah-Seung emphasizes: "This first construction site with our SENNEBOGEN duty cycle crane for ROCS / NGE Fondations is a real success! Its versatility does not stop at civil engineering work, but we have also had this machine, which is unique in the Indian Ocean area, customized for many other requirements in our industry: for heavy-duty handling with a particularly strong 58 m boom, for special civil engineering work with the diaphragm wall grab, for extraction work and dreging with clamshell grab, orange peel grab and dragline bucket. For us, this crawler crane is an acquisition that we will use for the long-term development of our activities."

Jobsite video

Machine in use

Press images

Press images

Press images

Press images

Press images

![[Translate to English:]](/fileadmin/_processed_/d/e/csm_SENNEBOGEN_835_E_material_handler_port_Valet_und_Ott__1__smaller_4adbd6f9bf.jpeg)