EMR Group: Environmental Protection in Scrap Recycling

At the port of Amsterdam, EMR – a global leader in sustainable material recycling – operates one of its four sites in the Netherlands. Each year, approximately one million tons of metal are processed here, with a clear mission: to become a climate-neutral company that protects the planet by reusing discarded materials, extending their life cycle, and paving the way toward a truly circular economy. To meet this ambitious goal, EMR relies on an environmentally friendly fleet of SENNEBOGEN material handlers at its Amsterdam site – including two 875 E models, two EQ-Balancers, and one each 855 E and 840 E.

Sustainability as part of the company's DNA

EMR has around 150 recycling facilities in the UK, USA, Germany and the Netherlands. The company works internationally with industry, government bodies and the general public to turn end-of-life materials, including consumer products, end-of-life vehicles, and materials from industry, construction, and demolition, into valuable resources – making the circular economy a reality. The locations continuously invest in modern equipment, environmental technology, and safety solutions. In Amsterdam, these investments have included a more efficient shear, a state-of-the-art water treatment facility, and a comprehensive fire prevention system.

15.7 million tonnes of CO2 savingsCO2 savings through recycled scrap metal

At its Amsterdam site, EMR processes obsolete steel material from the Netherlands, Belgium, and Germany. The secondary resources are transported locally to manufacturer Tata Steel in a fully electric truck and shipped to international steel makers. Recycling is increasingly replacing the environmentally harmful mining and processing of iron ore for steel production – with remarkable results: the metal recycled by EMR saves around 15.7 million tons of CO2 in steel production every year compared to steel production using iron ore – equivalent to the annual CO2 emissions of a large city such as Rome.

powerful fleet of machines: 850 tons of scrap per hour

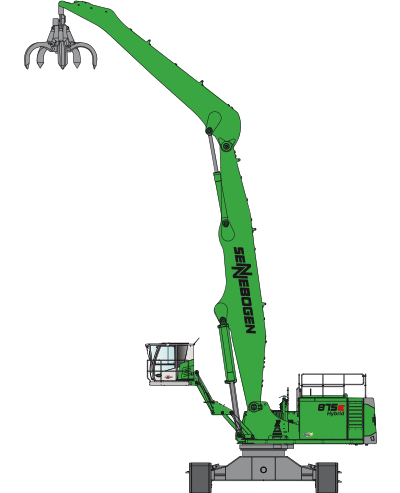

To efficiently handle these enormous quantities, EMR in Amsterdam relies on a powerful fleet of machines. Two SENNEBOGEN 875 E machines carry out the central material handling in Amsterdam. They handle everything from ships to unloading arriving trucks to loading the shears. The port material handlers impress with their handling capacity of up to 850 tons of metal per hour each, while maintaining low energy consumption. Thanks to the Green Hybrid recuperation system, operating costs can be reduced by up to 50%.

BALANCER MACHINES WITH 32-METRE RANGE

In addition, EMR relies on two electrically powered EQ balancers with an impressive range of 32 meters – ideal for stationary feeding of the shears and loading of the processed material.

Thanks to the directly coupled counterweight at the rear of the machine, the work equipment is perfectly balanced mechanically and energy consumption is reduced to a minimum. The EQ-Balancer consumes just 100 kWh during demanding scrap handling operations. In addition to their energy efficiency, the Balancers score points for their ease of use: “New, untrained drivers can work safely and productively on the machine after just one or two days – this gives us a lot of flexibility in our day-to-day operations,” explains site manager Martijn Vens.

As a global metal recycling company, EMR aims to combine high handling performance with sustainable processes. To achieve this, the company consistently relies on SENNEBOGEN material handlers, which optimally combine reliability, high efficiency and environmental friendliness.

Machines in use

Press images

Press images

Press images

Press images

Press images

Press images