Danish recycler relies on electric material handling solution from SENNEBOGEN as part of its new environmental strategy

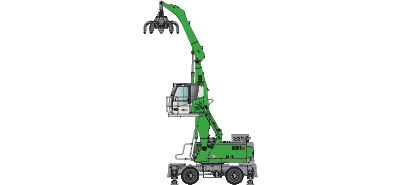

The environmentally conscious company Marius Pedersen A/S from Denmark handles many tonnes of waste every day. The investment in a new SENNEBOGEN 821 Mobile electric material handler now enables a sustainable and efficient way of handling waste with zero emissions.

Marius Pedersen is one of those companies that have developed a completely new environmental strategy for emission-free recycling in the future. As part of this out-of-the-box thinking restructuring process, those responsible put their focus to reducing the environmental impact of their waste management activities. Thanks to the implementation of an innovative electrically powered material handler from SENNEBOGEN by the responsible sales and service partner UN Mobilkraner, the processes have been completely modernized.

In an interview after the successful implementation, SENNEBOGEN spoke to the project partners, Ronnie Fegge, Regional Manager at Marius Pedersen A/S, and project manager Morten Espersen from UN Mobilkraner A/S, SENNEBOGEN's sales and service partner, about the company's reorientation and why it is now time to switch to alternative drives.

SENNEBOGEN: Mr. Fegge, you are relying on an electrically powered material handler. Why is it essential for you to rethink your company’s strategy right now?

Ronnie Fegge: In 2016, we carried out a series of renovation work at Marius Pedersen and started to make the company fit for the future. We simply had to keep up with current technology, and this involved switching to systems that provide power capacity for electrical machines when their use becomes relevant. As a recycling company, we are all the more pleased that we have been able to reduce the environmental impact of our daily operations and improve the working environment with the new SENNEBOGEN. It is a pure win-win situation for us, as the machine requires less maintenance and expects a longer service life.

SENNEBOGEN: With more than 30 years of experience in the project planning of electrical material handling solutions, we have already been able to implement numerous special projects and convince our customers of alternative drive options. What was decisive for you to have the 821 Mobile equipped with an electric drive?

Ronnie Fegge: First, we created the infrastructure during the renovation work, then we had to replace some of our machines and set out to find the right solution to meet our requirements. In Sweden we finally had the opportunity to see an electrically operated SENNEBOGEN in action. We put the machine through its paces there to find out whether the Swedish approach would be transferable to our case: an application in the hall with very low ceiling heights, but still flexibly movable to make the best possible use of the storage space in the large hall. And then we were no longer in doubt. We made a good agreement with UN Mobilkraner for the delivery of such a machine – this enabled us to give this megatrend around alternative drive systems a chance in our company as well.

SENNEBOGEN: Mr. Espersen, as the project manager, how were you finally able to convince your contacts at Marius Pedersen of the mobile electrical version of the 821 E series?

Morten Espersen: After our joint visit to Sweden, we hardly had to do much persuasion. The case of the Swedish recycler was very similar, which is why those responsible at Marius Pedersen have now made a good and far-sighted decision. We are very pleased to have delivered a new, electrically driven material handler to a company that previously relied entirely on diesel driven machines. A completely new approach, but one that shows all the more that in many cases an electric alternative can work. With the mobile electrical solution from SENNEBOGEN, the company not only saves fuel and thus operating costs, but also reduces emissions of nitrogen oxides and fine dust particles. This is wise considering the company's new environmental strategy.

SENNEBOGEN: Finally, Mr. Fegge, we would like to talk to you about the project planning itself. Can you sum up your experience?

Ronnie Fegge: The cooperation with UN Mobilkraner, our SENNEBOGEN dealer, was satisfactory in every respect. Delivery and commissioning worked perfectly. What impressed me most, however, was the company's commitment. One week after the machine was delivered, for example, we received an unsolicited visit from our contact person who just wanted to stop by and make sure that everything was as it should be. And since then, they have always been within reach – even for minor problems they are available to us promptly, quickly and in an uncomplicated manner with advice and assistance. In our opinion, this is a major plus.