Investing in the future: Recycling company Menshen expands its fleet with two new SENNEBOGEN material handlers

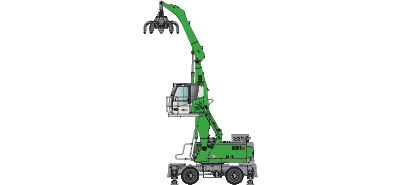

To handle the wide variety of materials on site and to invest in the future – it is for these two reasons that specialist recycling company A. Menshen GmbH & Co. KG in Werdohl, North Rhein-Westphalia, Germany decided to add two additional material handlers from SENNEBOGEN to their fleet. The recycler has a holistic approach to handling all types of waste material including non-ferrous metals, scrap steel, construction waste, bulky waste and waste paper. Seven green material handlers work side by side there, including, since 2018 two new mobile 821 E series. The agile machines are very versatile and are used both inside and outside across the 70,000 m² site.

Over the course of 60 years, family-run business A. Menshen GmbH & Co. KG has developed from the one-man operation founded by Arnold Menshen, into the internationally active recycling company that it is today, employing around 60 people at its Werdohl site. Although it is part of a globally active corporate group with over 2700 employees, the traditional values of the family company have not been lost. Just as with the family-run company SENNEBOGEN, tradition, trust and reliability play a major role in all company matters. It is hardly surprising, therefore, to find that purchasing decisions are not based purely on economic factors, but are made with an eye to the future.

A decision that benefits the environment

Paramount in the company's future-oriented economic decisions is whether the company itself and the environment will benefit from the acquisition in the long-term, e.g. through better energy efficiency, long-lasting components and lower particulate matter and noise emissions.

Menshen's deliberations with SENNEBOGEN and sales and service partner BRR-Baumaschinen Rhein-Ruhr GmbH, who plan to work together in the future too, were also based on many years of experience and trust between the partners.

"After working with SENNEBOGEN machines for 200,000 operational hours and experiencing BRR's after sales service, it was clear to me that there was no alternative. The machines are robust, economical and durable. Needing to buy a new machine after a short period of time is, in many ways, not justifiable," explains Thomas Busche, Technical Manager at the Werdohl site. By processing residual materials and putting them back into circulation, the company makes a positive contribution to materials recycling on a daily basis. The decision to procure two new 821 Mobile E series was made in the knowledge that, with proper maintenance, they will have long service lives.

Conserving resources

In order to make the on-site processes as efficient as possible, the SENNEBOGEN machines are in constant use at Menshen. Their tight day-to-day business includes unloading trucks, feeding the indoor scrap press and sorting materials outdoors. In these circumstances, energy efficiency and low fuel consumption are essential requirements for operating the machines. "Heavy machinery will always remain heavy machinery," says Busche. "But the fuel consumption of SENNEBOGEN machines compared to others on the market was a key factor in our purchasing decision. 9.6 liters of diesel per hour when carrying out demanding tasks saves money and is also acceptable in our ecological balance sheet."

What makes the 24 ton material handlers so efficient? The standard built-in SENNEBOGEN Green Efficiency System: Thanks to the hydraulic components being perfectly tuned to the engine, the optimal amount of hydraulic oil is supplied to the machine's circuit depending on the respective task and its lifting force required. EcoMode and stop and idle automation also contribute to the reduction of unnecessary fuel consumption without needing input from the operator. All these factors mean that machine components, such as pumps and valves, suffer less stress, which in turn, lengthens their service life.

Focus on people

The company's most important assets should not be left out when making long-term decisions. As well as the environment, the people who operate the machines must benefit from the investment. Machine operators, who spend eight hours or more a day in their work environment, need a space where they feel comfortable and safe.

The operator Maxcab from SENNEBOGEN is the ideal workspace. There is the option to have all windows made from bullet proof glass or protected by additional safety guards. The equipment and the roof are fitted with powerful LED-spotlights in order to illuminate the work area as best as possible and ensure the best visibility in dark indoor spaces. Furthermore, the comfortable operator's seat is equipped with air-suspension to relieve back strain.

"By investing in another SENNEBOGEN machine we have made the right decision on every level. We are looking forward to many more years of working together," concludes Thomas Busche.

Machine in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images