Three SENNEBOGEN material handlers in the heart of Zwickau: Scrap recycler Scholz puts third machine into operation

Another mobile 830 SENNEBOGEN material handler was recently put into operation in Zwickau, Saxony. Scrap expert Scholz Recycling GmbH, which employs a total of 39 people at the location, opted for a flexible, heavy-duty solution to streamline its business processes.

Zwickau is considered a relatively young location for the German automobile industry in reunited Germany. Ever since the 1990s, vehicles from a major German automotive manufacturer have been rolling off the line here, providing employment to the local populace. At the same time, the amount of old and new scrap has also begun to grow.

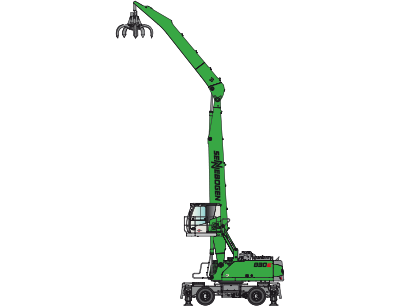

Each year, Scholz Recycling in Zwickau moves and transports 32.5 kilotons of old scrap and 95 kilotons of new scrap – a volume requiring efficient, heavy-duty machinery. To complement existing SENNEBOGEN machines – a stationary electrical solution with a 4-point undercarriage at the center of the location and an older, mobile 825 material handler – a mobile 830 E with reinforced undercarriage was introduced in 2018.

Fleet expansion for greater efficiency

“As we now have to prepare 12,000 t of delivered new and old scrap for transport across Europe each month, a machine upgrade was essential. With the new 830 mobile handler from SENNEBOGEN, we can now respond to larger scrap volumes with much greater flexibility,” states Marc Schaefer, purchase manager at the Zwickau location.

The fleet has now been expanded with a lease-purchase from SENNENBOGEN subsidiary Rental & Used: The mobile 830 moves and unloads old and new scrap with a range of 17 meters and a grab volume of up to 800 liters. It fits perfectly into the processes on site by supplying the stationary electric handler with material for the shears, which shred steel for subsequent transport. Thanks to the cab elevation, drivers work conveniently and safely at a visible height of 5.7 m, with excellent visibility over their work area.

Reduced operating costs offer competitive edge

“In the past, we have had very positive experiences with SENNEBOGEN, as the company provided us with efficient, tailored solutions,” states Schaefer, explaining the new purchase. “Both the stationary electric material handler and the two 825 and 830 mobile material handlers won us over with their durability, long service life and low operating costs in day-to-day operations.”

This is all made possible thanks to the standard Green Efficiency system for SENNEBOGEN diesel mobile material handlers: Idle and stop automation systems help reduce unnecessary fuel consumption, for example. Plus, the motor speed can be adjusted up or down depending on the force required for the job – functions that make the material handler more efficient overall and that provide a key competitive edge over the long term.

Machines in use

Press images

Press images