A traditional company on the banks of the Rhine chooses the SENNEBOGEN 870 E Freyer Hafenlogistik receives support from Lower Bavaria

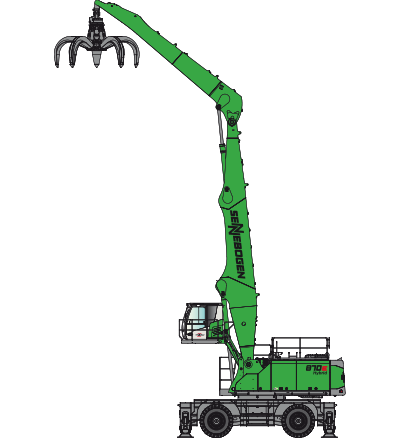

There's a new eyecatcher at the Germersheim inland port: Family-owned company Freyer Hafenlogistik is starting 2019 with an 870 E-Series mobile material handler. With a 2-meter-tall pylon, the port machine weighs an impressive 110 tons, yet remains maneuverable and flexible.

The philosophy of family businesses is largely the same no matter where you go: great diligence and tradition, as well as long-standing and reliable partners with whom you can form excellent cooperative relationships. One such family business is Freyer Hafenlogistik in Germersheim am Rhein, Germany, which is now in its fourth generation. In 1902, the great-grandfather of the current managing director, Peter Freyer, began mining gravel and sand in Neckarsulm. In 1969, the business was successfully relocated to the port of Germersheim and underwent a transformation. Since then, everything has revolved around the loading and unloading of ships.

“Our field of activity has become much more varied over the years. For us, keeping up with the times meant being able to react more flexibly to market requirements. That’s why we have expanded our repertoire since the turn of the millennium and now serve the field of port logistics as a whole. In addition to gravel and sand, we now deal with a wide variety of goods, including scrap and crude iron as well as grain and fertilizers”, says 71-year-old senior manager Erich Freyer when asked about the further development of the business.

Fleet expansion for even more flexibility in the port

At the beginning of 2019, Freyer further developed its fleet with the new 870 E mobile material handler from SENNEBOGEN in order to provide the required flexibility. In addition to two older 305 telehandlers and a smaller 860 from SENNEBOGEN’s D-series, the new port machine fits perfectly into the onsite processes. Thanks to the machine, which has a total length of 25 m, all the ships arriving at the port can be served. During the project planning phase, done in cooperation with Schlüter Baumaschinen, it was particularly important to ensure the filling of the existing 16-m-high silo. Thanks to the generous boom length and high stability of the 110-ton machine, this is no problem at all.

Another remarkable aspect is the volume that can now be handled following the machine upgrade. Within just 2.5 h, ships arriving in Germersheim with around 2,000 tons of gravel can be completely emptied. In total, the 27-man site transports 350,000 tons of bulk and general cargo each year.

“Of course, we don’t make machine decisions just like that. As a family business, we must consider things very carefully. We were extremely impressed with the mobile 870 E from SENNEBOGEN. It features the smallest yet most stable mobile undercarriage on the market. This allows us to be agile on site and use the machine flexibly,” explains Peter Freyer.

A further criterion in addition to flexibility in the port was the sensitive joystick control, which lets the driver handle the heavy loads comfortably and precisely. Despite its compact design, the spacious Maxcab offers the necessary space for comfortable and ergonomic work. It boasts an air-suspended seat with back support and climate control. In addition to the standard camera equipment at the rear and on the right, Freyer had an additional camera mounted on the compact boom for safety reasons; this supports the driver when filling the silo.

Since 2009, Freyer has been working successfully with SENNEBOGEN dealer and service partner Schlüter Baumaschinen – also a family-run business, and which is part of the Germersheim port logistics company's trusted circle of partners.

Machine in use

Press images

Press images

Press images