Recycling without refueling: SENNEBOGEN 821 Electro convinces at Baetsen-Groep in the Netherlands

The new SENNEBOGEN 821 Electro that Baetsen Recycling has been using since July 2014 in the Dutch town of Son, is always ready for work without refueling. Electrically powered, the machine not only saves energy, it is also particularly easy on the environment.

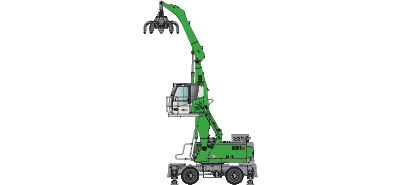

Founded in the 1960s as a small transport company, the family-run company, Baetsen, headquartered in Veldhoven, in the Netherlands, quickly advanced. Initially still with horse-drawn vehicles, later with a growing clientele and extended fields of business, today the Baetsen name stands for a comprehensive spectrum of services associated with transport and the disposal of building materials as well as crane hire, waste containers, excavation and demolition. At the Ekkersrijt location on 8.5 hectares, with two modern sorting plants, for construction waste and demolition waste the delivered material is sorted into 21 partial flows in sophisticated processes. Recently a new SENNEBOGEN 821 Electro has been positioned at the beginning of this process chain; it is powered by a powerful 90 kW electric motor, and it handles the pre-sorting.

The task of the new machine, which replaces a earthworks material handler that has reached the end of its service life, is to sort the delivered building and demolition materials into eight different grading categories. Positioned centrally on a ramp, the driver has an overview from the comfortable, ergonomic Maxcab, and with a reach of 11 m the machine can safely reach even the most remote sorting boxes. The new 821 machine of the current E-Series works approximately ten hours a day and thus sorts up to 120,000 t of material a year. For facility manager, Marc Peperkamp, the advantages of the machine are self-evident. Up to 50% savings in energy costs and operating costs, lower maintenance costs and less downtime, increased effectiveness thanks to the absence of refueling stops, were the decision criteria for this machine. Thanks to the robust crawler undercarriage, the machine is not only extremely stable, it also moves easily along the sorting boxes. It is not just the special material handling characteristics with ULM stick and sorting grab, but also the extended reach that are additional advantages as compared with the predecessor machine. Supplemental LED headlights and multiple surrounding cameras offer an ideal all-round view, even in bad weather.

For the first time, Baetsen is relying on a SENNEBOGEN material handling machine here, which the local Sales and Service Partner, Kuiken N.V. delivered in the customer's color and with special equipment. Kuiken N.V. handles the regular service and offers a reliable spare parts supply, with an extensive service network in the Netherlands and thus was able to convince the customer with the well thought-out machine concept.

Machine in use

Press images

Press images

Press images

Press images