Mobile port handling at BLG Logistics: energy-saving and flexible

"Something big is headed our way," Andre Heidkrüger of BLG Logistics may have thought as the new SENNEBOGEN 875 mobile crane arrived at the Port of Neustadt (Bremen) in March 2014. The new port crane has been unloading incoming ships for a short time now, and has proven itself with its flexibility and ease of use. Particularly remarkable are the mobile undercarriage and an intelligent energy recovery system.

This is something the founders of Bremer Lagerhaus Gesellschaft would not have dared dream of back when they started the company in 1877. Over the course of more than a century, what started as a small, regional association has grown into a logistics company spanning the globe. The bringing of cargo into the wide world through ports has always been a model for success. In the mid-1990s, the BLG Logistics Group grew from a local port handling company into an international logistics service provider. From shipping containers to automobiles, it moves material along every route of transport. Back in Bremen, where it all began, cargo handling is still alive and well today, and with the new SENNEBOGEN 875 mobile crane, it has been given a big boost.

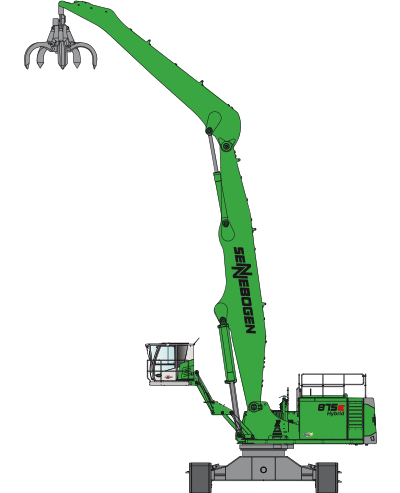

Gigantic, mobile crane at the port - 4 axles, 165 tons, 27-meter range

Since mid-2014, the new SENNEBOGEN 875 mobile crane has been providing its services at the quay as a handling machine that is both innovative and efficient. In close cooperation with SENNEBOGEN and dealer BRR Baumaschinen Rhein-Ruhr, Heidkrüger and his colleagues at BLG searched for and found the ideal machine for their wide range of challenges.

The 165-ton handling machine on the move with its mobile undercarriage is an imposing sight. A four-axle, wide-gauge undercarriage that is fully hydraulically driven allows the 875 to reach speeds of up to 5 kph. Loading and unloading incoming ships goes just as quickly. Just a few hours after arriving, these ships must depart once again for the high seas, carrying shipping containers, general cargo, large-diameter pipes, timber products, whole industrial machines and heavy cargo.

BLG Cargo Logistics operates with the Port of Neustadt in Bremen, Europe's largest terminal for conventional freight. Every year, around two million tons of cargo are handled - a challenge both to man and machine. The new port crane's day-to-day cargo largely consists of timber products and large-diameter pipes. Depending on the cargo, a cycle takes just about two minutes, which is a substantial increase in efficiency over the previous rope crane. More importantly, however, the machine can be used at different locations at the port thanks to its mobile undercarriage. Various attachments, from cargo fasteners to vacuum crossbeams, can be switched out quickly on the go. With a range of up to 27 meters, even the largest ships can be serviced confidently.

Saving energy with every stroke - Green Hybrid system proves itself

For the people in charge at BLG, the decisive factors were the high flexibility and mobility, as well as the low operating and service costs. The innovative SENNEBOGEN Green Hybrid energy recovery system saves up to 30% more energy than conventional concepts. The principle is easy to understand. A third hydraulic cylinder, placed directly between the two hoist cylinders, stores the energy produced by lowering the boom in compressed gas cylinders. This accumulated energy is then provided during the next stroke. The principle is similar to a spring being compressed and then releasing its energy when it is allowed to expand.

But what would even the best machine be without a good operator? For operators, the elevating Maxcab industrial cab provides an ideal overview of the work area, even into the ship's cargo hold. Simple maintenance tasks can also be completed quickly thanks to the machine's clear design. The SENCON smart control system provides all machine parameters and data on a clear display. For regular maintenance and replacement parts, BRR Baumaschinen Rhein-Ruhr is a capable SENNEBOGEN sales and service partner.

Dieser Artikel ist auch erschienen unter:

press.lectura.de

bi-constructionnews.com

Machine in use

Press images

Press images

Press images

Press images