Log yard wood processing: perfect machine wanted

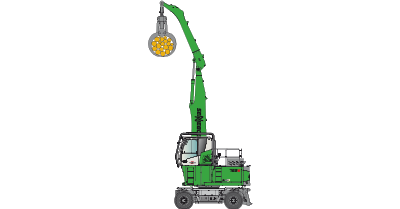

For the sorting of logs and the handling of wood goods, Ludwig Züfle Holzwerk from Baiersbronn - Mitteltal has invested in a new 723 E material handler from SENNEBOGEN. The machine was sold and delivered by Schlüter, a SENNEBOGEN sales and service partner. Product Sales Manager Michael Köhnlein officially released the new SENNEBOGEN 723 E for work with the traditional handover of the keys to Ludwig Züfle.

woodwork company Züfle relies on sustainability

Ludwig Züfle Holzwerk, located in Baiersbronn, is a family-run wood processing company. Already 40 years ago, Züfle specialized in the processing of pine, douglas fir and larch. These wood species grow very slowly in their native environment in the Black Forest as well as other specific locations and have a quality similar to Nordic woods: fine-grained and small-branched. These special quality criteria distinguish the Züfle Holz brand.

Züfle's product range extends from terrace and balcony decking to facade timbers and the manufacture of log cabins and carports. Other services include the cutting of domestic woods, the drying and planing of high-quality wood goods, and pressure impregnation for wood protection. The focus of production is always on sustainability: Ludwig Züfle Holzwerk has been PEFC and FSC certified for many years and generates electricity via several solar plants to reduce CO₂ emissions during production.

1.25 m² grapple for cutting to length and sorting logs

Ludwig Züfle Holzwerk GmbH needs the right machine for efficient and sustainable timber handling and has therefore invested in a new timber handler from SENNEBOGEN.

The 723 E is equipped with a 1.25 m² grapple and is responsible for cutting to length and sorting logs after they have been delivered to the log yard. Thanks to its compact dimensions, the handling machine can be maneuvered quickly and easily over the entire company premises. The powerful traction drive allows the 723 E to master slopes and difficult surfaces without any problems, while the machine accelerates to up to 20 km/h.

Continuous operation requires reliability of all machine components

In order to be prepared for the rough conditions in the saw mill, the reliability of all machine components is particularly important. For this reason, the undercarriage and upper carriage of the SENNEBOGEN 723 E are particularly robust, the travel drive and the axles are optimized for continuous operation, and the operator can reach all relevant points safely and comfortably for maintenance and service. In addition, an impact protection on the undercarriage, the standard full protective guard on the cab and an all-round gallery protect man and machine in daily operation.

operator comfort and maximum safety

Of course, operator comfort is not neglected in the 723 E: From the elevated cab, the operator has the best view of his work area. Thanks to the machine's compact dimensions and a low rear swing radius, the material handler can operate safely even in narrow alleys. The endlessly rotating upper carriage and automatic direction recognition not only ensure fast work processes, but also offer maximum safety.

Machine in use

Press images

Press images

Press images