Increased flexibility in the gravel pit

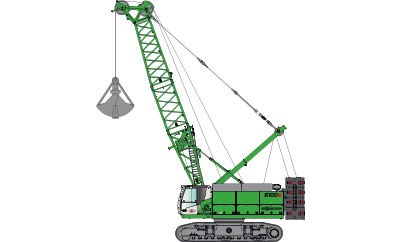

With the expansion of the extraction area, the Bokshorn gravel pit also needed to purchase new extraction equipment: effectiveness and flexibility were at the top of the list of requirements. With the SENNEBOGEN 6100 E duty cycle crane, the gravel pit found a tailor-made solution that not only perfectly meets its needs, but also scores points with its low consumption.

Gravel pit extraction area expanded

The Bokshorn gravel pit in Porta Westfalica, Germany, is a family business with a long tradition. Founded in 1882, the gravel plant—now in its third location—still produces around 150,000 tons of sand and gravel annually for the concrete industry, including prefabricated construction and paving stone factories. When the current managing partner Henrik Franke took over the business from his father in 2024, the gravel pit's extraction area was expanded. In order to be prepared for the new area, the machinery also needed to be updated in time. The old electric but inflexible scraper system was therefore replaced by the 100-ton SENNEBOGEN 6100 HD duty cycle crane.

Tailor-made for the job

"When I was looking for a more flexible solution for our expanded quarrying area, I quickly came across SENNEBOGEN's duty cycle cranes. Through the sales partner Louis Scheuch, we were able to test the concept with a 70-ton rental machine and ultimately decided on the 100-ton duty cycle crane with a 3.5 cubic yard dragline bucket," reports the managing director of the gravel plant. “For us, effectiveness is more important than speed. We want to operate sustainably and exploit the full capacity of the gravel pit. That’s why the desired digging depth of 12 m determined the size of the machine.” Thanks to the fairlead and the deflection rollers integrated into the boom, the cable of the duty cycle crane is guided optimally and gently. The machine and dragline bucket can be controlled safely and precisely, and dredging can be carried out gently and with the utmost accuracy. The 29.9 m long lattice boom, which is ideal for heavy, dynamic operation in the gravel pit, also allows the material to be picked up with the dragline bucket far in front of the machine, thus leaving the edge standing for as long as possible.

Flexible across the entire site

“All in all, the new duty cycle crane solution is significantly more efficient, elegant, and flexible than before. And not just in terms of location,” Franke continues. Thanks to the crawler undercarriage, the gravel plant employees can easily move the 6100 HD to wherever it is needed at any given moment. The areas of application for which it has been used so far are correspondingly diverse: from renaturation measures to digging a canal for the undisturbed water supply to the pump – a task that would otherwise have had to be contracted out to an external company. The machine is currently back in use in the old extraction area. This is no problem for the new flexible duty cycle crane which, unlike the old machine, does not require a power supply.

“We usually operate the SENNEBOGEN 6100 E at low speeds, so fuel consumption is pleasingly low. The machine still has enough power for our purposes,” says Franke happily.

Duty cycle crane project: A complete success

The duty cycle crane project has been a complete success: from the initial contact with Louis Scheuch, to the provision of a rental machine, to the final installation on site. The machine operators Yury Starodub and Alexander Chernishov also gave purely positive feedback. They are proud that they were able to master the complex application so quickly.

Machine in use

Press images

Press images

Press images

Press images