Frankfurt FOUR: Demanding special civil engineering by SENNEBOGEN Quintet for high-rise ensemble in the heart of Frankfurt

The "FOUR" project in the city centre of Frankfurt am Main poses great challenges for all companies involved. It comprises four futuristic high-rise buildings and is intended to reconnect an area that has been separated from urban life for decades with the city centre. Under difficult conditions, the extensive foundation engineering work will continue until spring 2020. The partner at the side: numerous large machines, including five SENNEBOGEN HD cycle cranes and crawler cranes. These were provided by sales and service partner " IBS Industrie- und Baumaschinen Service GmbH" from the rental park of the SENNEBOGEN Vertriebsgesellschaft (SVG) for this major project.

Four high-rise buildings are currently under construction on the former Deutsche Bank site: two office towers up to 228 m high with 55 storeys, a 173 m high residential tower that will be one of the tallest residential towers in Germany and a 120 m high high-rise building with condominiums. In addition to a hotel, serviced apartments and office space, a total of around 600 apartments are also being built. The basis for the four towers is a multifunctional building foundation. Civil engineering work started in spring 2019, and the shell of the high-rise buildings will begin after completion in autumn 2020. Completion of the construction and extension work is scheduled for 2023. Currently, the project is progressing in large steps according to plan.

Major contract for IBS GmbH and the "gentle" giants of SENNEBOGEN

With such a huge project, it's like a bank robbery: without the right "accomplices", it won't work. It all begins with the machine distribution. SENNEBOGEN SVG, whose rental park enables customers to rent machines on a project-specific basis in the medium or long term or fill gaps in the machine park at short notice, has enabled IBS to place and make available the five large SENNEBOGEN machines. IBS GmbH, in turn, has been a sales and service partner for SENNEBOGEN's cranes and material handling machines since 2002. Managing Director Walter Fischer himself and a large part of the 30-person team have been involved in the industry for many years and bring extensive and valuable expertise to the company in Central Franconia: With the sale, service and rental of industrial and construction machinery, the family-run company has achieved a leading position in the international market.

The foundation engineering work for Project Four initially includes the construction of the excavation pit enclosure using the diaphragm wall method. The foundation of the high-rise buildings will be carried out as a combined pile-slab foundation, which will require the construction of approx. 380 large bored piles (210 of which are column piles) with diameters of up to 2.0 m. In order to be able to construct the basement levels in a cover construction method, primary colums are installed in the foundation piles.

One of the challenges associated with the project ist hat the primary colums must be moved with great accuracy in the deep piles in terms of height, but also in lateral alignment". As "gentle" giants, the SENNEBOGEN heavy machines are the method of choice here: Thanks to sensitive control, heavy loads can be positioned precisely and easy.

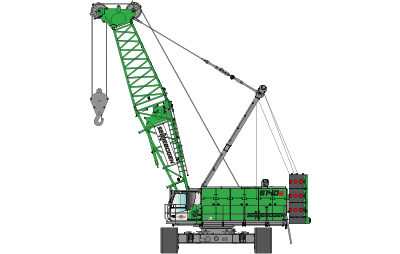

Heavy machines as specialists for special civil engineering: SENNEBOGEN HD Cycle Cranes 6130, 6140 and Crawler Cranes 3300 und 5500

Within the extensive construction site, even the large machines used lose their dominant effect. The focus here is on "heavyweights" such as the SENNEBOGEN crawler cranes and duty cycle cranes for diaphragm wall applications.

Specifically, this involves a 6140 R duty cycle crane and two 6130 R duty cycle cranes for diaphragm wall applications and the two 5500 R and 3300 R crawler cranes for crane applications. Even the delivery with 33 m long low-bed trailers in the narrow alleys was a logistical masterpiece, which will have to be repeated next spring when the foundation engineering work is completed. In the middle of Frankfurt's banking district, construction site logistics naturally presents the team with some difficulties when it comes to the delivery and removal of equipment and materials.

A clear plus for the schedule and budget: thanks to their compact dimensions and simple self-assembly, SENNEBOGEN crawler cranes do not require the help of additional cranes and can be assembled in just a few steps. All components have been optimised for cost-saving transport in containers, so assembly is also space-saving.

Challenging tasks for the 180 t crawler crane & 130 t duty cycle crane: MOVE BIG THINGS and diaphragm wall application

The ultimate heavyweight is the SENNEBOGEN 5500 crawler crane, which is suitable for lifting up to 180 t (optionally even up to 200 t) and is mainly used for moving and installing the primary columns in the piles. With dimensions of approx. 1 x 1 x 20 m, one primary column weighs up to 40 t. Due to the required large outreach, a machine of the size of the 5500 was required.

An important stage of the project: The production of the suspension-supported piles is carried out with pipes to a depth of approx. 10 m. Afterwards, the borehole is drilled to a final depth of approx. 45 m without casing and the soil is supported by a supporting fluid. Once the borehole is desanded, the reinforcement cage can be adjusted. The 5500 can provide support here as a Pick & Carry machine because, like any SENNEBOGEN crawler crane, it can move with up to 90% of its maximum load on the hook.

One of the two 6130 is used to bring down the reinforcement cage. This is where one of its strengths as a SENNEBOGEN duty cycle crane comes into play: to move big things - naturally with maximum stability thanks to the robust wide-track undercarriage. To position the column precisely, a quiver in the form of a large steel box is installed. This allows the precast column to be guided and prevents damage to the reinforcement cage. Once the box is precisely positioned, the concrete is placed and the column is then lifted into the finished pile. A procedure that is very demanding and for which the SENNEBOGEN 5500 R crawler crane has proven to be the ideal machine. The SENNEBOGEN duty cycle cranes in diaphragm wall applications also prove to be very reliable and efficient as usual.

„The customer is very satisfied with this - and so are we", says Walter Fischer, IBS.

Thanks to its high load capacity of 24 t across a work area of 20 m it can both operate heavy attachments in grab mode and also move heavy loads. On this construction site, the clay is a compact Frankfurt Clay, which repeatedly shows limestone banks as intermediate layers with varying thickness and sometimes great strength. The SENNEBOGEN 6140 E with its 350 kN free-fall winches can also operate the heavy diaphragm wall grabs that are necessary for this.

The project would also be technically challenging if it were to be built on a greenfield site. Here, under the tight conditions of Frankfurt's inner city, the task is many times greater. But despite all the difficulties that challenge the team every day: being allowed to work on such a project is a highlight for everyone involved.

![[Translate to English:] SENNEBOGEN 5500 E Crawler Crawler crane pictogram](/fileadmin/1_Produkte/10_Raupenkran/5500/Piktogramme_Maschinenbeschriftung/5500_e_serie_raupe_NEU_01.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_SENNEBOGEN-355-telescopic_handler-recycling_industry__2__3ce0081c3b.jpg)