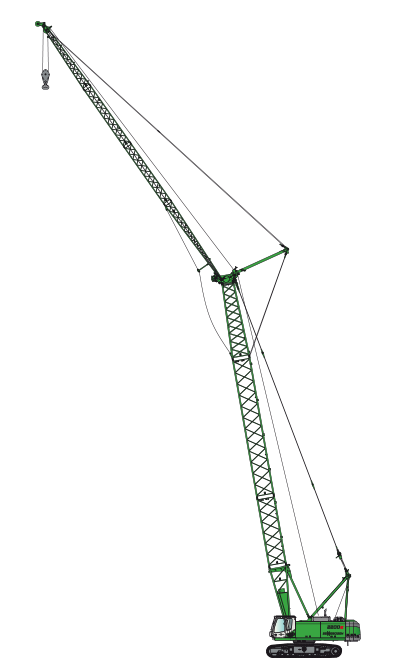

De Klerk Werkendam relies on a SENNEBOGEN 2200 E crawler crane for quay restoration

On behalf of FeedValid from Poederooijen / NL, De Klerk Werkendam is refurbishing the landing stage at the factory's quay with an 80 t SENNEBOGEN crawler crane. The crawler crane was supplied by sales and service partner Van Den Heuvel Cranes & Services B.V.

From various production and storage locations, family-run company FeedValid supplies customers both within Europe and further afield with raw materials for animal feed. A factory quay that provides trouble-free berthing for different types of transport ships is important. They have, therefore, decided to refurbish the important parts of the landing stage.

A SENNEBOGEN 2200 E crawler crane is being used for this. Its tasks include removing the existing stabilizers and piling, installing three new tube piles, transferring and adjusting a pile and installing new stabilizers complete with landing equipment.

The piles are inserted using a compaction attachment, the crawler crane holding the vibrator on the hook of its 31.7 m lattice boom. The compaction attachment lifts the piles, lowers them into position and then drives them several meters down into the ground. Hard work. The SENNEBOGEN 2200 E is the perfect partner for De Klerk Werkendam - a strong, stable crane with a 186 kW and 120 kN winch and a large load capacity that also fits into the confined space of a ship - it ticks all the boxes. The responsive steering, a winch tensile force of two times 85 kN and a high cable speed mean that the crawler crane has no problems positioning its load precisely and securely.

It sits firmly and securely on the crane ship, thanks to its telescopic crawler undercarriage and will ensure that the landing stage is back in use very soon. The comfort Maxcab, which can elevate by up to 2.7 m and tilt backwards by 20°, provides the operator with the best working conditions and the overview required.

Machine in use

Press images

Press images

![[Translate to English:] Pedersen Group gains a power house to help with tough jobs - the SENNEBOGEN 830 trailer handles timber in the Southern Hemisphere](/fileadmin/_processed_/4/e/csm_201904_830_M_Holzumschlag_Trailer_Australien_Pedersen_Group__6__bearb_1ef3027bb0.jpg)