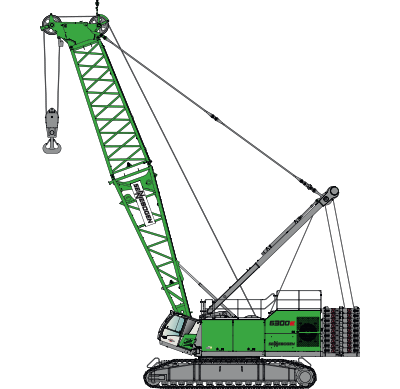

300 t heavy duty cycle crane - premiere at the bauma 2016

SENNEBOGEN presents its largest duty cycle crane with a safe working load of 300 t and engine power of up to 1150 hp for the first time at the bauma 2016 in Munich, Germany. With an especially high hydraulic capacity and convenient safe working loads, the heavy duty cycle crane is optimally suited to difficult dredging applications, mining, and demanding special underground engineering.

With the development of the SENNEBOGEN 6300 HD 300 t duty cycle crane, SENNEBOGEN takes into account the increased requirements of modern large-scale projects and impresses with high hydraulic capacities and powerful freefall winches with up to 450 kN pulling force.

Managing Director Erich Sennebogen explains, "With the latest SENEBOGEN 6300, we have a duty cycle crane that surpasses everything that has come before it. Every part has been designed for maximum durability, the base frame is solid steel to ideally absorb forces during continuous use, and we have also spared no expense in high-quality, solid components. We are currently expanding our production areas in Plant 2 in order to have the organization required to process future orders."

Three powerful engine variants from 570 kW to 840 kW open up diverse applications. Dredging applications with up to 15 m³ grapple volume are just as possible as mining with a large drag-line bucket or special underground engineering measures. In particular the high hydraulic capacity of the duty cycle crane is important for this. Attachments can be operated directly via the machine with up to 350 bar working pressure. Even the transport dimensions promise great things. The huge duty cycle crane measures an entire 12 m in length. The crawler tracks alone are 9.5 m long, with a track width of 6.8 m for stability and easy maneuverability. The sturdy uppercarriage and the solid counterweight plates bring the machine to a prestigious overall weight of 310 t. The proven SENNEBOGEN modular concept opens up diverse equipment variants, such as an 80 m long main boom that is available for use with lifting hooks, and different attachments can be hydraulically operated, depending on the application.

The modern Maxcab comfort cab provides the operator with an ergonomic work environment and an optimum overview of the work area.

The SENNEBOGEN 6300 E-Series – in summary

- Powerful: Three motor variants 570 kW/708 kW/840 kW

- Flexible use: Operate various attachments with up to 350 bar working pressure

- Winches: Strong winches with 450 kN pulling force

- Heavy duty equipment: Sturdy design and reliability for demanding applications in dredging, mining, or special underground engineering

- Easy maintenance: Centrally accessible maintenance points, clear design

- Maxcab comfort cab for continuously relaxed work and an excellent overview

Machine in use

Press images