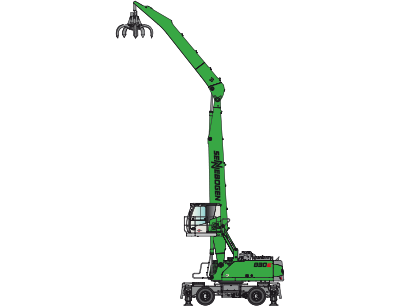

Versatile implementation: SENNEBOGEN 830 with Vario Tool at the scrapyard

Recently, the Welsh scrap and demolition service provider has been successfully using a new SENNEBOGEN 830 M with Vario Tool. With scrap metal shears or multi-shell grab, the machine is the equipment of choice - at the scrapyard and for demolition.

The family-run company, Phoenix Metal, founded in 1994, processes approximately 250 t of scrap every week at the Gwynedd location in Wales. Material from industrial and commercial operations, as well as from the surrounding households is delivered here daily. The responsible UK and Ireland - Sennebogen Port Sales and Service Partner, E. H. Hassell and Sons, was able to deliver a SENNEBOGEN 830 M in March 2014, as the second machine for this site. The machine is equipped with the SENNEBOGEN Vario Tool, the fully hydraulic, multi-functional changing system that enables use of scrap metal shears and grapples on one machine. The advantages of this system are clearly evident for operator Elwyn Davies. "We use the new SENNEBOGEN 830 as multi-functional demolition machine. For the first time, with just one machine we can safely demolish industrial structures and structural steelwork on site with the attached scrap metal shears, and then also immediately load the material. As the operator, I can change the attachments on my own with the aid of the automatic coupling - this saves time and money."

At Phoenix Metal the two attachments are safety loaded on a Ro/Ro container and brought to the implementation site by truck. Thus in just two minutes, the operator can easily and safely change attachment and stick from the driver seat. The dust-proof coupling guard prevents grime from penetrating and ensures long-term reliable function. Thanks to a 3.00 m transport width, the SENNEBOGEN 830 M can be placed on a flatbed trailer and thus also arrives safely and quickly at the implementation site.

The large 4.4 t Genesis XP 400 R scrap metal shears are particularly advantageous at the company's scrapyard. The 830 M breaks down the material, which is delivered from a surrounding area of approximately 100 km, or picked up with the company's own Ro/Ro containers, into easy-to-handle parts in preparation for subsequent further processing. The decision for an additional SENNEBOGEN machine was not difficult for owner Alwyn Davies, due to the good experiences with the predecessor model. In particular, the functional Vario Tool, a reliable concept without complicated electronics with easy handling and maintenance, convinced the responsible parties.

The machine is equipped with a fuel-saving 164 kW diesel engine and the 13 m VT boom. From a height of 5.60 m, the comfortable, elevating Maxcab offers the operator an ideal overview of the work environment and the highest level of safety. Moreover, with optimized motor settings, Eco Mode, and idle stop automation, the 830 machine of the current E-series is decidedly fuel-efficient.

Statement:

"With the new SENNEBOGEN 830 M E-Series, thanks to the Vario Tool system we have a multi-functional machine for demolition and scrap implementation. Whether on site at the implementation location, or at our scrapyard, the 830 M is always ideally equipped", explains operator operator Elwyn Davies, Phoenix Metal

Image caption:

Equipment with the multi-functional Vario Tool, Phoenix Metal flexibly deploys the new SENNEBOGEN 830 M E-Series with Genesis XP 400 R scrap metal shears or multi-shell grab.

Machine in use

Press images

Press images

Press images

Press images

Press images