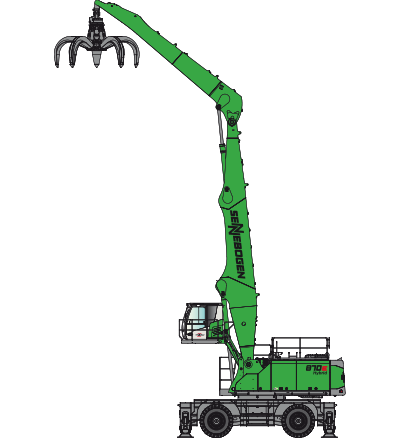

Product launch: SENNEBOGEN 870 E-Series with Green Hybrid energy recovery

At bauma 2016, SENNEBOGEN will introduce the new 870 material handler for demanding material handling at ports, scrapyards, or for industrial use. The newly developed product boasts a convenient safe working load of 8 t at a maximum reach of up to 25 m, as well as the innovative Green Hybrid energy recovery system.

The SENNEBOGEN material handlers of the Green Line have proven themselves in demanding tasks across the globe with reliable technology, minimal operating costs and innovative, custom solutions for any challenge.

As the latest model in the current E-Series, the SENNEBOGEN 870 comes with a powerful 261-kW diesel engine complying with Tier 4f emission standards, including automatic idle stop and EcoMode. A 250-kW electric motor is also available. With equipment lengths up to 25 m at a maximum safe working load of 8 t, the latest model in the current E-Series supersedes its predecessors with vastly increased performance.

Green Hybrid system saves up to 30% in energy through energy recovery

The innovative Green Hybrid energy recovery system is the latest development and is fitted to both the SENNEBOGEN 875 and the new 870. This system has been proven through initial customer use across the globe. An energy recovery cylinder mounted on the boom in between the two hoist cylinders offsets the weight of the boom, reducing energy costs up to 30%. This additional hydraulic cylinder stores the energy produced by lowering the boom in compressed gas cylinders placed in the rear of the machine. This accumulated energy is then provided during the next stroke. The principle is similar to a spring being compressed and then releasing its energy when it is allowed to expand.

Maximum comfort and ideal overview for port handling applications

The new SENNEBOGEN 870 offers operators a comfortable work space with an ideal overview from the Maxcab cab which can be elevated as standard. The largest Maxcab Industry cab with glass bottom or the spacious Mastercab with training seat are available as options, especially for use at ports. All cabs offer the operator a pleasant workplace with automatic air-conditioning and high-precision joystick control. The new material handler is available with a new option: the newly developed Skylift cab extensions allow access from the ground and views up to 15 m with ease. This allows, e.g., the monitoring of loading operations into ship hulls, a valuable safety feature in port handling.

The proven SENNEBOGEN modular concept offers an extensive range of superstructure variants to meet customer requirements. From a mobile undercarriage with 4-point claw support to crawler and rail undercarriages, to gantry and pylon solutions for special port applications, all can be provided as custom solutions. With gantry and pylon superstructures in particular, the SENNEBOGEN 870 achieves an outstanding viewing height for use in material handling. The custom modular system consisting of several undercarriage variants, various equipment lengths, cabs and cab extensions allows for more than 1,000 flexible combinations – the right solution for any challenge.

Easy to maintain and easy to use

In daily operations the SENNEBOGEN 870 distinguishes itself by its ease of maintenance and servicing. The walk-on uppercarriage with continuous gallery ensures uncomplicated access to maintenance and service points. A service/maintenance box in the uppercarriage makes it easy to check and conveniently service the entire machine with just a few actions. Typical for SENNEBOGEN in this regard is the clear arrangement of all components, with the proven longitudinal installation of the engine offering service advantages. The SENNEBOGEN Control System, or SENCON in short, offers easy menu navigation. Machine parameters can be read out centrally on a generously proportioned, intuitively operated display, and the operator can conveniently make individual fine adjustments himself.

The SENNEBOGEN 870 E-Series: overview

The new E-Series of the SENNEBOGEN 870 supplements the extensive range of Green Line material handlers for port handling and scrapyard applications. Versatile configurations are available for such operations, allowing the machine to be tailored to customer-specific requirements.

- Top-level performance:

Cummins Tier 4f 261-kW diesel engine

Alternative: 250 kW 400 V 50/60 Hz electric motor - Superior safe working loads: up to 8 t at 25 m reach

- Versatile equipment: lengths from 18 m to 25 m

- Flexible modular system: mobile undercarriage, crawler undercarriage, pylon variants, gantry solutions, rail undercarriages

- Modern Maxcab comfort cab for continuously relaxed work, optional vertical and horizontal adjustment, other special variants available

- Highest safety standards: easily accessible maintenance points via walk-on uppercarriage, railing and gallery on the cab and uppercarriage, LED headlights, peripheral cameras right and rear

- Energy-saving drives: all machines are optionally available with electro-hydraulic drive solutions, with the Green Hybrid energy recovery system for savings up to 30% being fitted as standard.

Image caption:

With the new 870, SENNEBOGEN provides a material handler with a reach of 25 m and numerous variants designed specifically for port handling.

Machine in use

Press images

Press images