Port handling on a large scale: Elzinga relies on new SENNEBOGEN 870 E-Series

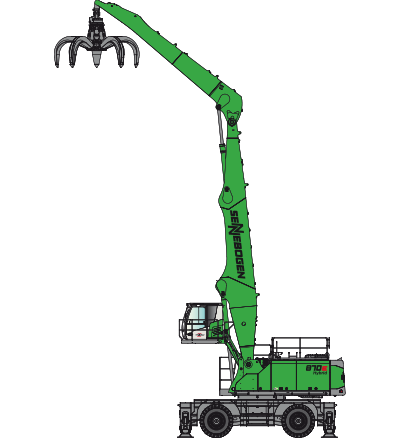

In early 2016, the first mobile SENNEBOGEN 870 E-Series was to go to the Elzinga Group in the Netherlands. The material handler is used in the port with impressive handling performance and a maximum reach of 24 m.

Since SENNEBOGEN and the Elzinga company from Eemshaven, Netherlands can look back on many years of successful cooperation, it is no surprise that the first mobile port material handler of the new 870 generation went to the Netherlands. In the north-west of the country, Elzinga Groep handles around 3 million tons of bulk goods and cargo in Eemshaven annually. Especially when large ships have to be unloaded in a very short time, fast cycles and safe working are decisive criteria for operators and the people responsible for the machine park. With the new 870 material handler, which is handled by the sales and service partner Kuiken B.V, the company is prepared for all eventualities.

Maximum efficiency thanks to Green Hybrid energy recovery

In the new generation, the SENNEBOGEN 870 E-Series comes with a 261 kW diesel engine that meets the requirements of the TIER 4f exhaust regulation. An energy recovery system ensures that the installed power can be lower and that energy can be efficiently saved with each stroke. For this purpose, a third cylinder is mounted on the boom. When the equipment is lowered, the oil that it contains is displaced. The obtained energy is temporarily stored in four nitrogen accumulators in the rear, to be made available again to support the next stroke. This results in operating cost savings of up to 30%.

In addition to the innovative energy recovery system, the machine also impresses with the height-adjustable Skylift cab elevation. The spacious Mastercab, which also has a trainer's seat in addition to generous space for the operator, can be adjusted over a height of 10 m upwards and 7 m forwards. An uninterrupted view into the ship's hull during loading and maximum safety in daily work are the important advantages, operator Andries Vriesema confirms. It can also be comfortably and safely entered from the ground.

Innovative modular concept for customer-specific design

SENNEBOGEN traditionally offers a variety of equipment variants to adapt each machine individually to customer requirements. With various cab elevations, equipment lengths, or undercarriage variants, the machines can be individually configured in over 1000 variants. Whether with a crawler chassis or as a mobile version, the 870 can be configured with very different undercarriage variants depending on the intended purpose. The mobile undercarriage with 4-point swivel support outrigger that Elzinga operates is particularly impressive. The supports can be folded in for travelling and thus offer maximum mobility for applications over the entire port area. When standing, the supports ensure a large outrigger area and maximum stability even with large reaches of up to 24 m. As a further example of machine customization, the SENNEBOGEN 870 was equipped with an extensive seawater package. This includes, for example, a maritime climate-resistant varnishing and coated hydraulic cylinders.

In Eemshaven, Elzinga uses the new SENNEBOGEN 870 with 24 m long equipment primarily for loading ships. The uppercarriage is elevated by a 2 m mast, and a perimeter gallery creates optimum accessibility for maintenance and servicing.

Machine in use

Press images

Press images