Offshore in action: SENNEBOGEN Crawler Crane during Seaway Heavy Lifting

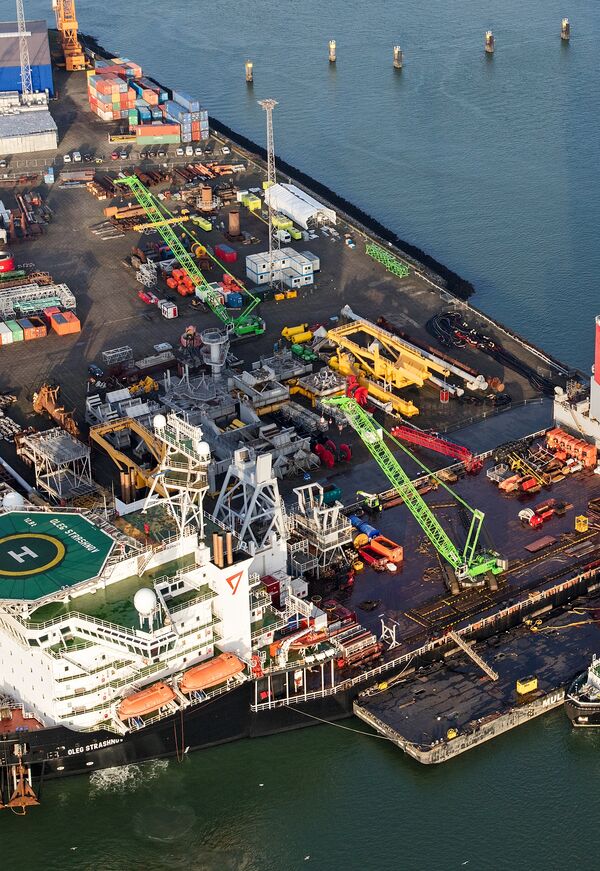

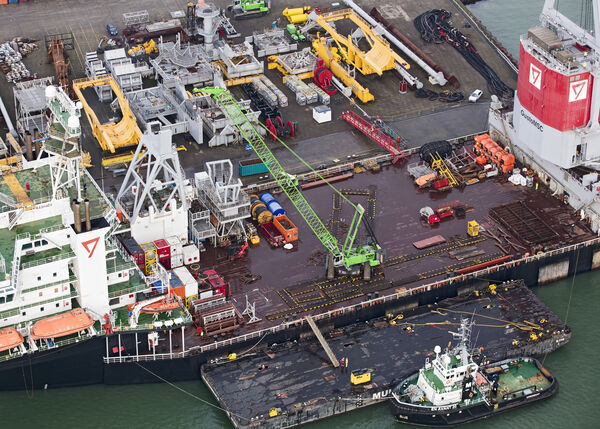

With its delivery of two crawler cranes – SENNEBOGEN 7700 (300ton) and SENNEBOGEN 5500 (180ton) - to Seaway Heavy Lifting, a leading offshore contractor in the global Oil & Gas and Renewables industry SENNEBOGEN again emphasizes its authority in designing individual cranes based on customer specifications. Both crawler cranes work offshore worldwide and are employed on the crane vessels Oleg Strashnov and Stanislav Yudin.

As one of the leading offshore contractors for the Oil & Gas and Renewables industry, Seaway Heavy Lifting offers its global customers offshore T&I (Transport and Installation) and EPCI (Engineering, Procurement, Constructions & Installation) solutions. In order to meet the logistics requirements of the Oleg Strashnov, a 5,000-t crane vessel, a new SENNEBOGEN crawler crane is used since the end of 2015. Although, when compared with the ship's own crane, the 300-t crawler crane is considerably smaller; however, its numerous special features are impressive. Powered by a mighty 313-kW diesel engine and equipped with two 200-kN crane hoists, the Sennebogen 7700 lifts the necessary material into any position on the ship's deck. To do this, special offshore load lift charts were computed in compliance with EN 13582-2. Dynamic parameters were taken into account and programmed into the LML (loadmoment limiter) of the machine.

Furthermore, both master winches are equipped with an "Emergency Load Release System (ELRS)". The system is compliant with the tighter safety requirements applicable to offshore equipment. Having a boom range of 46.7 m, dynamic loads of up to 60 t can be moved onboard the vessel.

Safety and reliability are the focus point

A very robust broad-gauge undercarriage makes the flexible movement on the ship's deck possible, while at the same time the framework is extremely stable and safe. For the demanding operation of the crane vessel, the SENNEBOGEN crawler crane was equipped with additional ballast and received a special paint for offshore operation. In order to bypass the diesel engine in case of an emergency, an electrohydraulic emergency unit was added to the crane's equipment. This makes it possible to operate all crane functions under full load, if necessary. For installation and maintenance tasks, the crane is equipped with a 3-t aerial work platform winch. The complete aerial work platforms system was designed in compliance with EN 13852-2. The A-frame was redesigned accordingly in order to prevent it from protruding over the counterweight during turning.

While considering the operator, the crane was equipped with an elevated operator's cab. And on a level of 4.5 m, the operator has an ideal overview of his work area. Furthermore, the cab can be tilted 20° which allows the operator to maintain a view of the crane's hook as well. The design of the machine is the result of the close teamwork between the customer, SENNEBOGEN, and distribution and service partner Kuiken B.V. After only the first few months, this teamwork has proven itself as being very successful.

A second machine – a SENNEBOGEN 5500 (180 t crawler crane) – is used onshore and employed to handle the logistics operation at the stockyard. It will be used in the near future on the crane vessel Stanislav Yudin and its 2,500-t master crane. The SENNEBOGEN 5500 is also equipped according to offshore specifications.

Statement:

"Both crawler cranes SENNEBOGEN 7700 and SENNEBOGEN 5500 have assured us of their capabilities in the shortest period of time – in close cooperation with Kuiken and SENNEBOGEN we were able to find an optimum solution for our demanding requirements in offshore applications" says Jop Gelders, Technical Superintendent – Seaway Heavy Lifting

Machines in use

Press images

Press images

![[Translate to English:] SENNEBOGEN 5500 E Crawler Crawler crane pictogram](/fileadmin/1_Produkte/10_Raupenkran/5500/Piktogramme_Maschinenbeschriftung/5500_e_serie_raupe_NEU_01.png)

![[Translate to English:]](/fileadmin/1_Produkte/10_Raupenkran/7700/Piktogramme_Maschinenbeschriftung/7700_e_serie_raupe_NEU_01.png)