Not just an appendage: A grab is much more than that

Performance – carrying out a defined task in a specific amount of time. Whether you are at work, at home or on the sports field, there are always two ways of optimizing performance: Get faster, or work more efficiently with optimized components. Just as, in motorsports, the right choice of tire can be the difference between defeat or victory, in material handling choosing the right grapple can optimize handling performance.

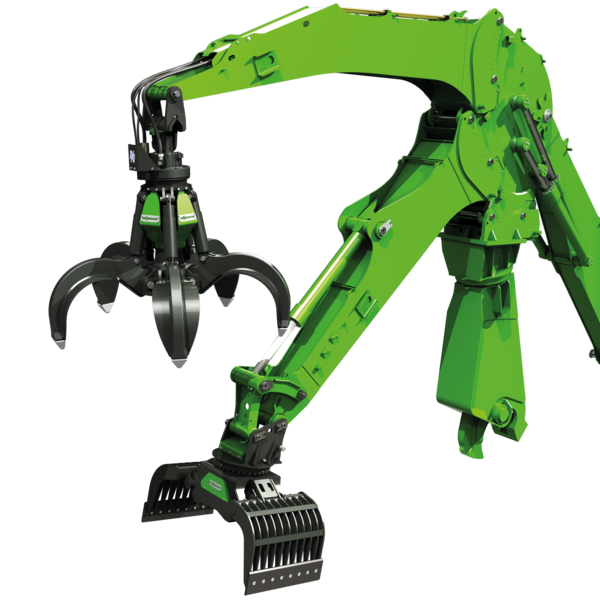

Our own grapple line – With its own range of grapples, SENNEBOGEN provides its customers with the ideal addition to help them work even more efficiently. The grapple portfolio ranges from multi-shell grabs with different shell shapes and double-shell grabs for all kinds of bulk goods to log grapples and other special attachments. All of these attachments are coordinated with the Green Line material handlers and optimized for the specific application requirements. This results in reduced loss, better performance, and lower fuel consumption.uch.

The right grapple for every material

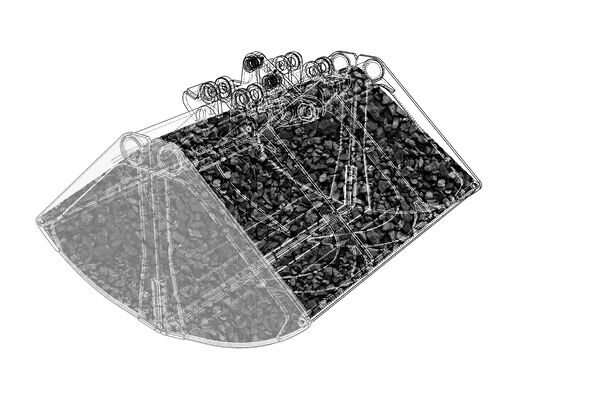

Different materials need different types of grapple: Scrap handling often requires rapid opening and closing whereas, in the case of bulk goods handling, it is important to find the ideal shell shape for the material in question. Ultimately, the various materials behave differently due to their composition and texture – they may or may not be suited to stacking; they may flow or pile up. All of this needs to be taken into account when choosing the right grapple.

Bathtub for wood pellets – pyramid for coal – When wood pellets are being unloaded, they behave like water and flow in all directions in the grapple once it has closed. Coal, on the other hand, piles up when the grapple closes and gathers in the middle of the grapple. The more the shell shape is optimized for the material in question, the more material can be moved in a single load. Put simply, therefore, the shape of a bathtub is recommended for wood pellets, whereas a coal grapple is closed at the top and the pile resembles a pyramid shape.

Ultimately the grapple makes the difference – at the very least, optimizing the grapple machine configuration can improve the performance in many a handling situation.

4 or 5 shells? - In scrap handling applications in particular, the grapples on the material handlers are exposed to the toughest conditions. Multi-shell grabs are equally suitable for sensitive sorting tasks and for pulling apart bundles of scrap with force. The advantage of a 4-shell grapple over the 5-shell variant is the lower tare weight of the attachment. This increases the payload of the machine. At the same time, the 4-arm geometry allows the grapple to be lowered cleanly and easily into containers or other vessels. This means that even bulky materials can be picked up and moved easily and safely. There is a diverse range of variants available – for example, customers can choose between half-open and closed shells.

Optimum utilization even under continuous load

Wear – par for the course with grapples. But with the right design, maintenance work and loss of value can be kept to a minimum. All SENNEBOGEN two-shell and HD grapples are therefore fitted with screw-on wearing profiles as standard. This means that worn grapples can be repaired quickly and affordably so the grapple can work at full capacity once again.

Coordination – Ensuring that the machine and grapple are hydraulically coordinated is just as important as ensuring the attachment design is well thought through. Particular attention should be paid to optimizing oil flows, cross sections, and connections. The better coordinated the machine and the corresponding grapple, the more efficient, smooth, and loss-free the work will be. This will also have a direct effect on the performance of the material handler. Machine and grapple from a single source – this combination is the best solution for efficient material handling and will really pay off in practice.