New SENtrack telemetry system: fleet management system for SENNEBOGEN material handlers and cranes

With the introduction of its own SENtrack telemetry system, SENNEBOGEN offers a convenient, central platform for monitoring machine data worldwide, locating positions and for the effective planning of maintenance. The system will be able to provide in real-time the status of the machine, offering maintenance personnel and machine supervisors an attractive user interface for fleet management.

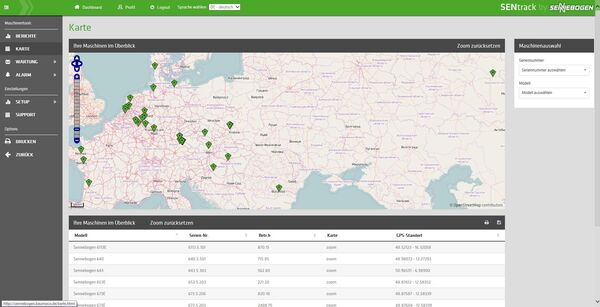

The SENtrack telemetry system now offers owners of SENNEBOGEN material handlers and cranes a way to manage their machinery more easily and with all the key information. The web-based user interface offers a centralized overview of all machinery in use as well as their movements. At the same time, SENtrack is also a tool for maintenance planning and control. For example, live data such as fuel consumption, engine temperature, hydraulic pressure and utilization rate can be determined wirelessly. At the same time, the data can also be easily traced over longer periods and the exact position of the machines can be determined on a map via GPS.

Monitor all machinery from your desk

The system provides an overview of all machinery that is especially beneficial to rental park owners. The dispatcher also quickly gains an overview of capacity utilization. Thanks to GPS, daily routes can be tracked on the premises, e.g., a wood processing plant, allowing them to be optimized.

With a custom login, machine supervisors can easily track all SENNEBOGEN machines, automatically view maintenance intervals and easily plan servicing in coordination with SENNEBOGEN sales and service partners. For example, the SENtrack system can display a visual notification when maintenance is due, immediately query the machine's status, send the location to the service technician and review the machine's key operating data.

In terms of hardware, the SENtrack module consists of a GSM and GPS antenna and a control unit in the uppercarriage of the machine that transmits the data via the cellular network. The user can conveniently access and analyze the data online. In the near future, new machines will have the option of being equipped with the system at the factory, while a retrofit kit is currently available from Customer Service for existing machines.

Captions:

From a monitor, the user has an overview of all machinery. Locations and machine data will be provided in real time.