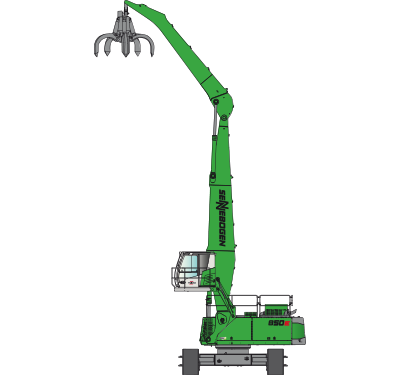

Handling Sand On A Large Scale: Spaansen B.V. using Green SENNEBOGEN 850 Material Handlers For Port Work

At bauma 2016, SENNEBOGEN introduced the new 850 E-Series, a mobile material handler for port handling. As one of the first implementations, the machine went to the Netherlands to handle sand for Spaansen.

During any construction project, raw materials such as sand and gravel are unavoidable construction materials. As a complete service provider, from sand extraction to path and road construction, the Dutch company Spaansen can meet any requirement. With its own extensive fleet of ships, material handlers and trucks, Spaansen guarantees the highest level of quality and reliability to customers nationwide.At the Ijmuiden port, Spaansen handles around four million tonnes of sand every year - and for a long time now, the company has put its faith in SENNEBOGEN material handlers. At the end of 2016, the first material handler from the new generation of SENNEBOGEN 850 E-Series machines went into operation, loading up to 900 tonnes of sand per hour.

An Innovative Green Hybrid System With A Reach Up to 21 m

With a reach of up to 21 m and a load capacity of up to 5.7 tonnes, the SENNEBOGEN 850 is ideal for meeting the requirements of port handling. Its curved banana boom can extend to a reach depth of up to 12 m, allowing large ships to be loaded safely. At the same time, hoppers at a height of up to 17 m can be operated safely. From the elevated cab, the driver has an idea view of the work area. The Maxcab can be continuously adjusted by 3.0 m in height and moved 2.60 m forward.

It is not just the exterior of the 850 that is green - the figures relating to its internal workings are also impressive. A 224 kW diesel engine keeps the material handler running smoothly. The system is supported by the innovative Green Hybrid energy recovery system. The functionality is simple to conceive: An energy recovery cylinder mounted on the boom in between the two hoist cylinders offsets the weight of the boom in its function, significantly reducing energy costs by up to 30%. This additional hydraulic cylinder stores the energy produced when the boom is lowered, in compressed gas cylinders placed in the rear of the machine. This accumulated energy is then provided during the next stroke. The principle is similar to a spring being compressed and then releasing its energy when it is allowed to expand.

At Spaansen, the decision was made a lot easier by the high degree of reliability of the system and its robust construction, as well as-of course-the low operating costs. With a wide gauge undercarriage and 4-point outrigger support, the material handler stands with reliable stability. Regular maintenance and servicing is conducted in a tried-and-tested manner by the competent sales partner Kuiken B.V.

Machine in use

Press images

Press images

Press images