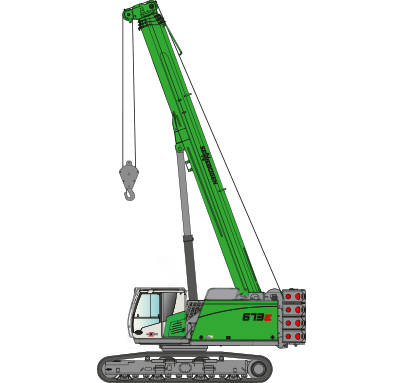

WORLD PREMIERE: SENNEBOGEN PRESENTS THE NEW 673 R-HD TELESCOPIC CRAWLER CRANE

For bauma 2013, SENNEBOGEN presents the new 673 telescopic crawler crane, a powerful 70 ton crane whose stable crawler tracks and continuously telescoping boom arm render it extremely flexible and reliable. The SENNEBOGEN 673 R-HD performs impressively on the job with its highly robust design, compact dimensions and superior working and safety features.

For more than 20 years, SENNEBOGEN telescopic cranes have embodied the optimum combination of flexibility, cost-effectiveness and quality. The new SENNEBOGEN 673 R-HD rounds out the broad product spectrum as the first telescopic crawler crane of the new E-series.

The 673 R-HD was designed for high performance. Thanks to its telescopic boom, the crane can handle any demanding job on the construction site. In comparison to other crane designs, the SENNEBOGEN telescopic crawler crane offers a host of advantages.

MAXIMUM DRIVER COMFORT AND A RANGE OF USES

The telescoping crawler tracks of the SENNEBOGEN 673 R-HD enables safe and flexible work. Thanks to a large four-point support base and wide baseplates, the machine can stand securely even in dynamic tasks on difficult terrain. The compact dimensions come in handy, particularly in narrow working spaces. In addition to its use as a crane, the 673 R-HD can also operate on a working platform rated to bear up to 1000 kg. This significantly expands the working range of the machine and enables a host of additional uses.

For the driver, the SENNEBOGEN Maxcab ergonomic cabin maximizes working comfort and ease of use. The comfortable joystick control, large sliding door, optional peripheral cameras and stable grating next to the cabin are all ergonomic features that simultaneously enhance safety. To provide an excellent view of the work area, the SENNEBOGEN 673 R-HD can optionally come equipped with an hydraulically elevated cabin. The cabin can be raised an additional 2.7 m and tilt up to 30 degrees to provide a commanding view – a unique solution in construction industry.

In addition, the SENNEBOGEN 673 R is very easy to service. The central lubrication point for all articulations and the slewing ring reduces the required amount of servicing, optimizes accessibility to servicing points and important components, and saves time during operation.

Machine in use

Press images

Press images