Tracking down the noise: How the quietest machines are produced at SENNEBOGEN

A high level of noise exposure makes people sick; a fact confirmed over and over by the relevant studies. For SENNEBOGEN this has been reason enough for its long involvement the subject of noise reduction. The example of the current E-Series shows how priority is placed on noise generation even during the product development phase.

At the latest with the development order for the "quietest material handler in the world" in 1989, SENNEBOGEN gained attention in noise reduction matters. At the time the development was awarded the Blue Angel (Blaue Engel) eco-label by the Bavarian Minister for the Environment - a success story that continues to the present day. Currently the latest generation of green material handling machines is impressive with the best values in terms of noise emission. The new SENNEBOGEN 821 is a striking example of just what is possible for protection of operator and environment.

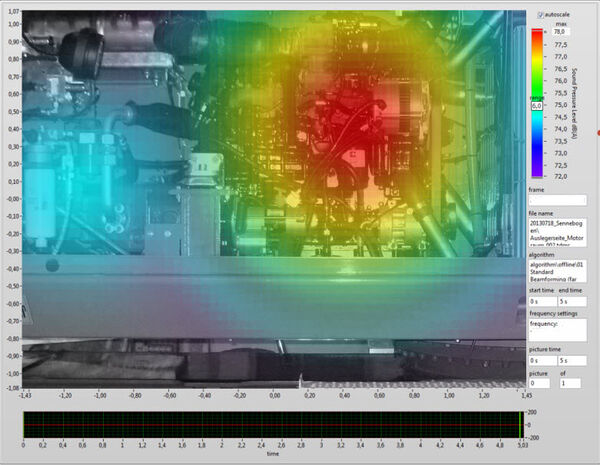

In the development process of a new machine, noise analysis take shape as early as the design phase. Recordings made with so-called acoustic cameras help to localize and effectively counteract the noise sources. In this process not infrequently small things can have major effects on noise generation. An effective method is minimization of sound and vibration transmission paths. For example, in the course of development of the new E-Series the motor bearings are decoupled from the outer sheet metal elements, to avoid resonant vibrations. Likewise it was important to provide elastic bearing support for secondary noise sources, such as hydraulic lines and cable harnesses, to avoid unnecessary resonance. The reason: Ultimately every component that is excited to oscillation represents a potential noise source. The extensive insulation of the uppercarriage is an effective means for reduction of noise emissions. For this the uppercarriage of the 821 E-Series was systematically lined with highly effective insulating mats.

SENNEBOGEN machines often work round-the-clock in difficult multi-shift implementation - this means that the most rigorous requirements are imposed on the cooling system. Attention is focused on this area. The calculation is simple: The easier it is for air to flow through the cooling system, the less noise is developed in the process. As to the predecessor, the new 821 was equipped with particularly large-dimensioned coolers and fans. Generous flow cross-sections allow the air to flow into the engine compartment with low resistance. Thus the necessary air volume can be moved at low RPMs. Reduced fan RPM accordingly means low air speeds and thus less noise development. An intelligent temperature-regulated control system ensures that the fan only runs when it actually must remove heat. The regulation of fan RPM also takes the ambient temperatures into account. The cooler the environment, the easier it is to dissipate the required heat and the fan RPMs can be kept at the lowest possible level. Positive side effect: This also reduces fuel consumption. In the extreme case the generous dimensioning of the cooling system even enables implementation at temperatures in excess of 50°C. At this bandwidth it becomes clear that SENNEBOGEN has not achieved noise optimization at the cost of the accustomed performance of the machine, but rather it is evident that SENNEBOGEN was already looking at the optimal interaction of all system components at the beginning of the development phase.

The noise optimization examples cited here make the machine audibly quieter, and they can also be confirmed in numeric values. Even the prototypes of the new SENNEBOGEN 821 E-Series achieved sound power levels of 99 dB and lower. Thus the new machine is 3 dB under the previous value achieved by the predecessor series, which effectively corresponds to cutting the sound power level in half.

SENNEBOGEN development engineer, Florian Krinner, summarizes: "Overall, through optimization of the machine we were able To reduce the sound power level by approximately 3 dB. This means that two machines of the current E-Series together do not generate any more noise than does a single machine of the predecessor generation." A study commissioned by the WHO concerning the effects of noise on our health and quality of life published in 2011 made it unmistakably clear just how harmful consistent noise exposure is. According to the study, during the day every third European is exposed to an excessive noise burden - lack of concentration, sleep disorders extending to cardiovascular complaints are the consequences. The classic implementation areas of the material handling machines are scrapyard's and recycling facilities. At these locations there a high noise level already prevails due to the environmental factors. Thus it is even more important to design the workplace of the machine operator as low-noise as possible inside as well as outside of the cab. With conversion to the Maxcab comfort cab it was possible to likewise lower the noise emission in the cab. Current measurements confirm values of 70 dB and lower.

Press images

Press images