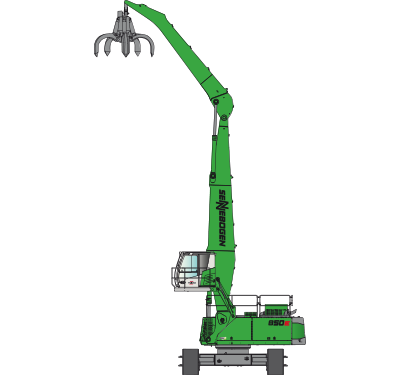

Space-saving and extra quiet: The SENNEBOGEN 850 R in Alkmaar

A new SENNEBOGEN 850 R recently began to unload incoming ships at the waterfront of the Dutch company de Vries & van de Wiel in Alkmaar. Located on the peninsula between the North Sea and IJsselmeer, the machine discharges sand by the tonne. The SENNEBOGEN is something special; the 850 R sits on a rail-guided carriage and can be driven fast on the waterfront. A special noise package permits a very calm and evenly quiet operation.

Excavation work, road and canal construction, and especially sand excavation are the main business fields of Vries & van de Wiel in Alkmaar. In addition, ships with up to 500 m³ of sand arrive at the waterfront daily. Recently, a new SENNEBOGEN 850 with double-shell grip began unloading the material. The machine replaces the previously used cable crane and, thanks to its concept, is revolutionizing the processes employed. With the 21-m long boom and a reach of 42 m, it can swivel back and forth quickly and safely between ship and hopper. Whereas around 400 tonnes per hour could be transferred previously, the new machine now does up to 650 tonnes in one hour. For SENNEBOGEN and Kuiken, the local sales and service partner, creating this machine was a significant challenge. In particular, the tight space and unusual proximity to neighboring residential neighborhoods had to be mastered. Together, they developed a customer-specific solution like no other. Since strict noise protection regulations allow a maximum sound level of only 51.5 dB during the day and just 35 dB at night, the partners, in cooperation with the company Cees Benchop, had to isolate the diesel machine in such a way that an impairment of the surroundings could be excluded. Thanks to its optimized sound insulation, the SENNEBOGEN 850 R fulfills these standards completely.

An additional task was positioning of the SENNEBOGEN on the narrow waterfront. The solution is a rail carriage. In the transfer process, the machine has to work beyond an existing concrete wall and, to let it swivel without hindrance, the track was quickly placed in an elevated position. This variant was ultimately carried out, together with HKS Metals. The rail carriage could be steered directly via the food pedal in the driver's cabin. The track drive with conventional diesel drive ensures that de Vries & van de Wiel enjoy enormous flexibility. Besides its use on the waterfront, the machine can be used flexibly at other locations. Complete handling of the sand transfer can be ensured with just two people. Drivers especially praise the uncomplicated handling and high transfer performance of the new machine. The difference from the previously used cable crane is large, they say. The maXcab comfort cab, which can be driven up, offers a grand overview of both the arriving ships and the hoppers and storage areas. The local sales partner Kuiken is responsible for maintenance and regular service and continues to support customers with words and deeds.

Machine in use

Press images

Press images