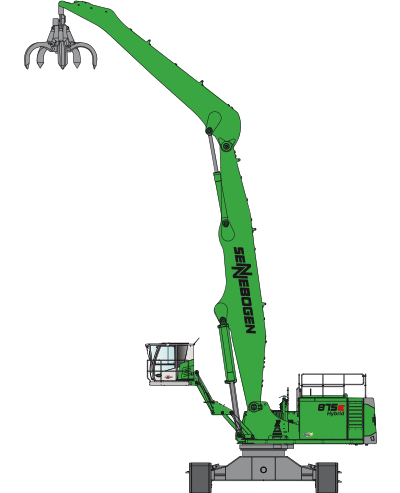

Hybrid material handler SENNEBOGEN 875 impresses with high performance in coal handling

The US company Robindale Energy has recently started using a new SENNEBOGEN 875 material handler for loading coal from ships on the Monongahela River in Pennsylvania, USA. Equipped with the Green Hybrid system, the machine unloads up to six jumbo barges per day.

Upon taking over the coal handling station on the Monongahela River, Paul Theodorakos, Equipment Manager at Robindale Energy, was confronted with the task of increasing the loading capacities. While the work was previously done with an earth-moving material handling machine, the plan was now to find a handling solution that was specially tailored to the circumstances. "All things quickly pointed to SENNEBOGEN," Equipment Manager Paul Theodorakos reports.

"I have been in the coal business for 39 years, but I had never had to take care of unloading ships before. The modified earth-moving machine from the 1990s was no longer able to provide the necessary handling performance. So I started to look for a solution."

The joint inspection of a SENNEBOGEN 875 at Charleston Bulk Transfer (CBT) in South Carolina, USA, where the machine loads up to 12,500 t of coal per day, finally clinched the decision. "Our host, Fabian Turner, President of CBT, was full of praise; the innovative Green Hybrid system in particular convinced me," Theodorakos looks back.

Energy savings of up to 30 percent with Green Hybrid technology

The innovative SENNEBOGEN Green Hybrid energy recovery system saves up to 30% more energy than conventional concepts. The principle is easy to understand. A third hydraulic cylinder, placed directly between the two hoist cylinders, stores the energy produced by lowering the boom in compressed gas cylinders. This accumulated energy is then provided during the next stroke. The principle is similar to a spring being compressed and then releasing its energy when it is allowed to expand.

At the same time that the new SENNEBOGEN 875 E was being built in the Bavarian town of Straubing, the work on the new dock began and a SENNEBOGEN 850 Mobile material handler was selected as an interim machine. When the sales partner Gibson Machinery was finally able to deliver the new 875 in the summer, Robindale Energy was so impressed with the smaller machine that they decided to add the 850 M as a replacement machine as well.

Maximum performance with minimum consumption is impressive

The new SENNEBOGEN 875 soon became indispensable, as Operations Manager John Ross confirms. With the attached 14 yd double shell grab, the machine unloads up to six jumbo barges per day. It has fulfilled all expectations. The barges are now emptied in less than 1.25 hours, which is no comparison to earlier times. At the same time, the material handler impresses with the best ergonomics and an optimum overview from the elevating Maxcab cab.

"However, the most important argument is the consumption," adds Ross. "During my 39 years of work, I have never seen such a large machine with such a low fuel consumption."

Caption:

A new SENNEBOGEN 875 material handler unloads coal barges at Donard Dock for Robindale Energy in Pennsylvania, USA.