Foundation work for railroad line extension with SENNEBOGEN cranes

The Verona-Padua high-speed rail project is part of the Turin-Milan-Venice line and belongs to the Mediterranean corridor of the Trans-European Network – a contribution of the European Union to the development of the internal market and the improvement of the economic and social cohesion of the region. As a construction company specialising in civil engineering, Fondamenta S.p.A. is taking care of the foundation work for the new railway line on the Verona-Vicenza section in northern Italy, which is scheduled to go into operation in 2027, and is using two telescopic cranes and a crawler crane from SENNEBOGEN for this purpose.

The Italian construction company Fondamenta S.p.A. has more than 30 years of experience in civil engineering and is specialised in special civil engineering and foundation work. As part of the Verona-Padua high-speed railway project, the company has been commissioned, among other things, to build the Fibbio Bridge, which, with its 2.3 km length, will be one of the most important viaducts of the section. The three SENNEBOGEN cranes used in this project were supplied by the Italian sales and service partner ESPI Engineering.

Tight schedule and narrow construction site

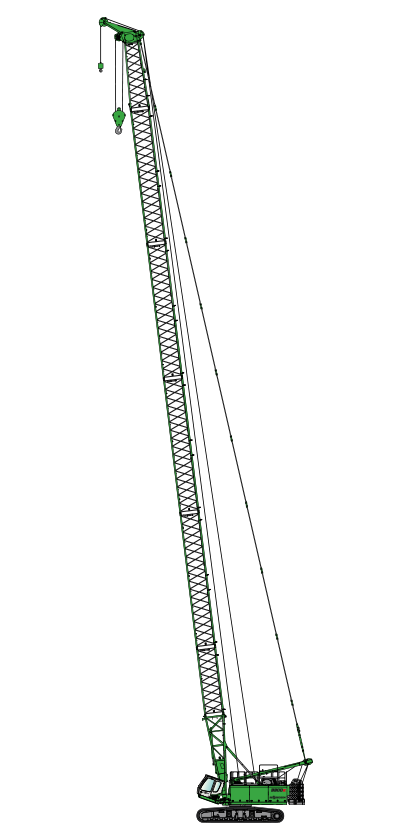

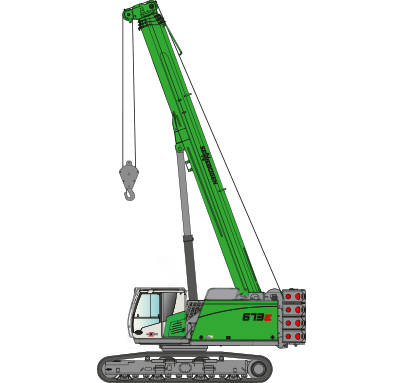

A total of 711 in-situ concrete piles have to be produced for this project within one year. In order to keep to this tight schedule, the SENNEBOGEN cranes used, the 50 t crawler crane 1100 E with a boom length of 52 m and the 70 t telescopic crane 673 E with a boom length of up to 36 m, work in parallel and perform the same tasks.

Site manager Nazario Sinigagliese explains: "A big challenge on this construction site is, among other things, that the route is located between a gas pipeline in the ground and an above-ground power line that is still being laid in the ground during the railway construction work. This means that all lifting, turning and pick and carry work has to be carried out particularly safely. That’s a reason why we rely on SENNEBOGEN cranes"

Making foundation piles and turning the reinforcement cages with auxiliary boom

The respective length of the piles to be set depends strongly on the type of subsoil. On average, the piles are approx. 40 m long, weigh 6.5 t and consist of four 12.5 m long and 1500 mm wide reinforcement cages, which are partly pushed into each other. These are first assembled to a long reinforcement cage with the 1100 E and the 673 E, then carefully inserted into the boreholes and finally filled with concrete.

When pouring the concrete, the machines insert the tremie pipe into the reinforcement cages and pull it out again sensitively during the filling process. Equipped with an auxiliary boom and a second winch, the actually tricky turning of the reinforcement cages from the horizontal to the vertical position becomes child's play, so to speak, for both cranes. Another crawler telescopic crane with a lifting capacity of 30 t is used to unload the reinforcement cages from the low-loaders and transport them to the interim storage facility.

Each crane has its advantages

The site manager's assistant, Luigi Alberto D'Andrea, explains the respective advantages of the two cranes: "Some crane operators prefer the 673 E telescopic crawler crane because it proves to be particularly flexible and versatile with regard to the varying activities on the construction site."

"Especially in confined spaces, the telescopic crane is very safe to work with. In addition, it is easy to transport and quick to assemble for changing jobs. The 50 t crawler crane 1100 E, on the other hand, convinces with its functionality, especially when additional equipment is needed. When vibrating, for example, the lattice boom ensures even greater stability and excellently compensates for vibrations."

Machines in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images