Flows of goods for over 100 years: SENNEBOGEN 875 unloads coal at the port of Murmansk

Ports are lynchpins of the modern economy. They connect countries and companies with each other. In the Russian city of Murmansk, tons of Siberian coal leave the port every day. The material is handled and loaded with a SENNEBOGEN 875 material handler.

In 2016 the largest city in the Arctic is celebrating its 100th anniversary. Named "Romanow-na-Murmana" in 1916 after the Russian czar, the "Cape Town of the North" is now known by the name Murmansk. Located in a bay of the Arctic Ocean, the city has always been shaped by the port. This has actually existed for one year longer than the city of the same name and was thus the origin of the economic growth of the region.

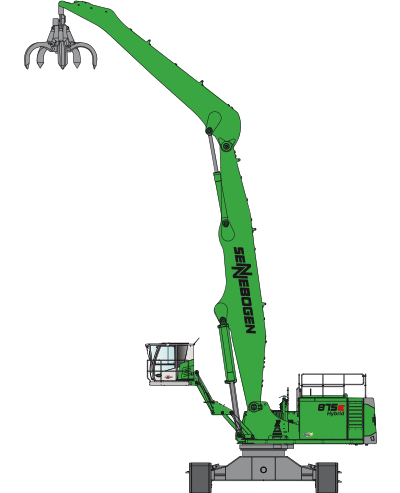

Efficient material handling with a portal undercarriage and a 24 m range

In the port of Murmansk, which extends for several kilometers along Kola Bay, mainly coal is handled on a large scale, in addition to single items, bulk goods, and containers. Up to 500 cars bring coal from the mining areas in Siberia via rail to the port of Murmansk. With the modern handling technology of SENNEBOGEN, the railcars are unloaded there, and the coal is stored in large stocks to be loaded on ships later. Equipped with a crawler portal undercarriage, the SENNEBOGEN 875 stands directly over the rails, in order to remove the coal with the 5 m³ double shell grab. Thanks to a track width of 5.80 m and a passage height of 5.0 m, the undercarriage spans one of the two railway lines but can comfortably serve both railway lines at the same time, one directly underneath the machine and one parallel to it. In addition, the diesel-driven material handler has a range of 24 m and alternately unloads the railcars on the right and left in a continuous cycle.

Operators of the machine agree: "The view from the elevated Mastercab comfort cab is perfect. In addition, cameras and LED headlights help provide optimum visibility even in bad weather conditions. Thanks to the powerful slewing drive with up to 5 revolutions per minute, we manage an unloading cycle in under 30 seconds – that is our fastest time!"

The machines that the responsible sales and service partner JSC KWINTMADI delivered in mid 2015 have a 395 kW diesel engine and the proven Green Hybrid energy recovery system. The 875 was optimized with a low temperature package for use at Artic temperatures. This includes numerous preheating mechanisms for the equipment and the Green Hybrid system, as well as special lubricants for temperatures down to minus 35 degrees Celsius.

For the employees of Murmansk Commercial Seaport, the reliability and availability of the SENNEBOGEN machines are paramount. With modern handling technology, they are equipped for the challenges of the increasing goods handling. In addition to the 875 with crawler portal, several SENNEBOGEN 830 and 835 material handlers are also in use in the port area. These load and transport all kinds of bulk goods. The competent service and regular maintenance by KwintMadi, which is represented by a branch in Murmansk, ensure maximum availability and guarantee a long service life for the machines.

Machine in use

Press images

Press images