Experience innovation - effective installation of electricity pylons with the SENNEBOGEN 673 at Himmel and Papesch

To meet the increasing requirements imposed on electricity pylon capacities, currently replacement construction of the 110 kV high-voltage line is underway between the Lower-Saxony town of Hemmoor and the regional capital, Cuxhaven. In a new procedure, steel solid-wall pylons are founded there with a SENNEBOGEN 673 telescopic crawler crane.

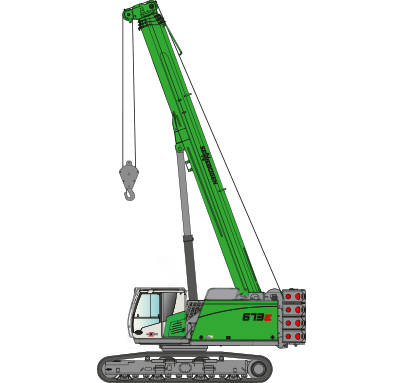

The picturesque region surrounding the Lower-Saxony municipality of Hemmoor is characterized by meadows, lakes, and particularly by countless moors. To meet the escalating requirements imposed on the power grid in the course of increased wind energy generation, on 35 km between Hemmoor and Cuxhaven a new 110 kV line is under construction. The company, Himmel und Papesch (HuP), headquartered in Bebra, in Hessen, was commissioned to erect the replacement line, and to do this, the firm is using a new SENNEBOGEN 673 R HD telescopic crawler crane with the utmost success.

Due to the special ground condition in the moor areas, in the route section near the municipality of Hemmoor, instead of the steel lattice construction, steel solid-wall pylons are driven in with a new procedure. First the existing lattice pylons are removed and the foundation is prepared for the new founding. Here, in the first step, the SENNEBOGEN 673 R-HD is used as a classic crane for the removal and loading of the pylons.

Things get interesting when the machine is used in combination with a Junttan hydraulic hammer. First the existing foundations are driven deeper into the ground with the 6 t drop weight to create space for the new founding. This is followed by a steel ring with a diameter of 2 m, which later delimits the concrete foundation. Using a pile frame developed by HuP, finally the driven casing foundations up to 15 m in length are driven vertically into the ground with millimeter precision.

The specialists require two to three days per mast with this new procedure - incredible time savings compared to other methods. The foundation can be subjected to load immediately and intervention in the nature landscape remains extremely minimal because the pylon can be erected at the same point as before.

With the SENNEBOGEN 673 of the current E-Series, HuP found the perfect machine for this demanding application. For the entire process and beyond, the 160 kW telescoping crawler crane with its 36 m boom length, is the equipment of choice. Because material and machines must be brought into new positions for each pylon, several times a week, high flexibility and minimal setup times are required. Thanks to the retractable crawler chassis and the innovative self-assembly system, the SENNEBOGEN 673 can be quickly changed over per flat-bed vehicle with only 3 m transport width, and then it is again immediately available for operation. The machine handles short distances itself and is also stable on difficult terrain.

In addition to the founding, the 673 R-HD is also used for installation of the power pylons that are up to 30 m in height. In this area, operator Dominik Andrea has particular praise for the maXcab comfort cab that be tilted by 20° - thus an optimal overview is always guaranteed.

"The SENNEBOGEN 673 is convincing with its good all-round view and a pleasant, ergonomic work environment. I can work much faster with the telescopic boom than I can with a comparable duty cycle crawler crane, this saves time and effort, explains Dominik Andrea. An extensive safety package, including peripheral cameras and the convenient SENNEBOGEN Control System, SENCON, also support him in daily operation.

Machine in use

Press images

Press images

Press images

Press images

Press images