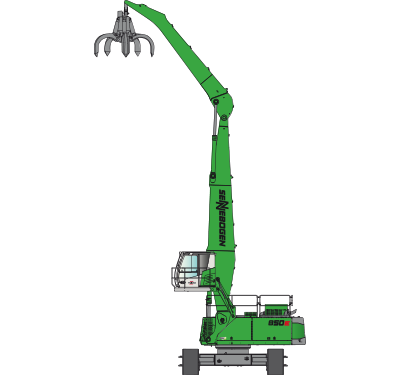

Electrical scrap handling: SENNEBOGEN 850 Crawler Special convinces at Max Becker

In line with the motto "by rail or truck to the harbor and from the Rhine across the seas", Max Becker Trading GmbH recycles all types of scrap metal at the port of Cologne Niehl, primarily relying on the dependable materials handling machines from SENNEBOGEN. The new 850 R Special Electro, which recently has been put to use for charging the scrap metal shears and for material sorting, has a promising future here.

Located in the heart of Cologne, Max Becker Trading GmbH has been an established entity in the field of scrap recycling since 1994. The first material handling machines from SENNEBOGEN were already active in the second year following establishment of the company. Last year, Sales and Service Partner, Baumaschinen Rhein-Ruhr (BRR), delivered a new SENNEBOGEN 850 R Special Electro. Two 835 M units round out the machine pool. They are used to move, sort, store and prepare the material by further processing by the metal scrap shears for further transport by ship.

At the customer's request, the 850 R Special was equipped with a 250 kW electric motor which yields a saving of about 50% of energy and operating costs as compared to the diesel-powered previous version. Even in stationary mode, the reach of over 20 meters easily covers an area of just under 1,300 square meters. Thanks to the stable crawler undercarriage with a 4.90 m track width, the machine is not only extremely safe but can also can be moved flexibly over the entire compound. To provide the necessary overview and reach for filling the scrap shears, the machine was elevated a total of 5.00 m by means of a tube pylon at the customer's request. Combined with the 1.00 m rigid cabin elevation, operator Lothar Lenzen has an ideal overview of his entire work area. In addition, the spacious Mastercab offers a high degree of operator comfort and ideal ergonomics. With the all-around glazing, including floor window of safety glass, the operator always has an overview. The extensive camera system and the LED lighting set ensure a safe work environment, even in poor weather.

After the first hours of operation, operators and supervisors draw a positive balance. The electric machine convinces through low energy consumption, and the motor offers constant performance in all load ranges. Extended maintenance intervals and lower service costs are additional benefits that have strong appeal for the owner. In daily operation, the lower level of background noise is an additional argument with which the SENNEBOGEN 850 R Special Electro can score points.

MOVING MATERIAL SAFELY AND WITH PINPOINT PRECISION: SENNEBOGEN MULTI-SHELL GRAB

The machine was delivered from the SENNEBOGEN factory with its 1,000-liter-capacity multi-shell grapple. The 5-shell semi-open grapple with forged tips is adjusted for optimal hydraulic use. Together, machine and attachment form a perfectly matched unit. Optimized hydraulic flow ensures fast opening and closing of the HGT 1000 and guarantees maximum closing forces. This is all the more important when bulky material must be moved safely and with pinpoint precision.