Heavy lifting work during the construction of complex industrial buildings

A new flax processing site with five units is being built in northern France. Three SENNEBOGEN construction site cranes are at the centre of the project: the 613 E compact telescopic crawler crane for handling and site preparation, the 2200 G crawler crane for assembling the main structures and the 3300 E crawler crane for heavy loads.

Goderville in Normandy, just a few kilometres from the English Channel: this is where the new flat processing and storage facility is being built. AGY LIN is building a processing plant, a maintenance workshop and administrative offices on a 70,000 m² site. The cooperative specialises in long and short fibre and seed production. In addition to a 7,000 m² main building, four further units of 3,000 m² each will be built. The realisation will be entrusted to the two companies of the same name, Thibault and Thibault Industrial Construction. Mutual complementarity is intended to guarantee efficiency.

Construction work began in spring 2023 with the laying of the foundations for the plant building and the excavation of a working pit to house the machine infrastructure for the flax handling process. Thibault took over this phase, using conventional construction methods for the foundations (reinforced concrete floor slabs, walls and ceilings). Thibault Industrial Construction undertook the assembly of prefabricated columns, beams and panels that form the structure of the buildings.

The key players for this extensive construction project: the SENNEBOGEN 613 E telescopic crawler crane and the two crawler cranes, SENNEBOGEN 2200 G and SENNEBOGEN 3300 E. Their different characteristics enable them to work perfectly together.

Compact manoeuvring on confined construction sites

The compact SENNEBOGEN 613 E telescopic crawler crane transports the formwork, reinforcements and concrete buckets during the preparatory phases and when building the pit required for processing the flax. The crane is also used to erect the metal scaffolding. Thanks to its small size and its unique ability to move under load and adjust the length of its telescopic boom under load, it can be used dynamically.

"With its elevating cab, the compact 613 E telescopic crane supports our fitters working at height in a coordinated manner. Crane operators and fitters have almost the same field of vision from their cabins. This is crucial for their safety," confirms Laurent Vauris, site manager, who is responsible for coordinating the construction site.

Diverse tasks during assembly

Thanks to its 80 tonne lifting capacity, the SENNEBOGEN 2200 G crawler crane is responsible for assembling the main structures. It enables the erection of the prefabricated columns and panels, various handling operations and the assembly of the administration building.

"We save valuable time"

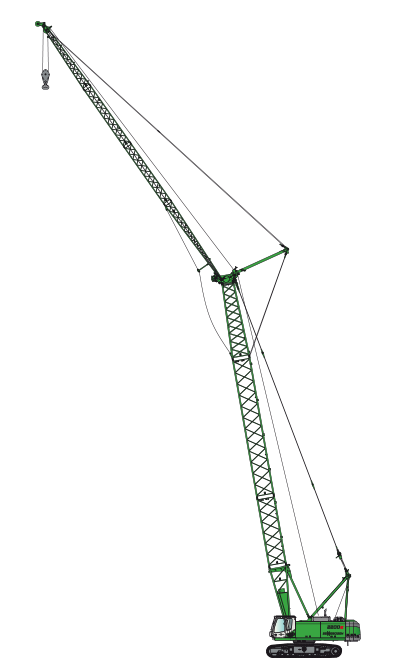

The latest crawler crane in the Thibault Industrial Construction fleet: a SENNEBOGEN 3300 E, a crawler crane with a lifting capacity of 125 tonnes, equipped with a main boom and a jib. David Baussard, crane operator and site manager, operates the new SENNEBOGEN crane:

"The 3300 E handles all the heavy lifting work on the construction site. The delivery process is very demanding in order to meet the sometimes very short delivery times for prefabricated elements. Even when inserting the heaviest beams, which weigh more than 30 tonnes, the crane takes over the lifting without having to adjust the equipment configuration. We save valuable time."

Benoît Thibault and Elise Lyskawa, the managers of Thibault and Thibault Industrial Construction, are delighted with the progress made on this major construction site: "The technical decisions we made with SYGMAT when purchasing our SENNEBOGEN cranes have been perfectly confirmed here. When constructing complex industrial buildings, coordination between the teams is crucial. This would be impossible without suitable transport and lifting equipment. Our SENNEBOGEN crawler cranes, from the most compact to the most powerful, ensure the safety of our employees and performance for our customers."

Machines in use

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images

Press images