Franz Bracht Kranvermietung GmbH counts on the flexibility and reliability of SENNEBOGEN telescopic crawler cranes for precast assembly and in the wind power industry

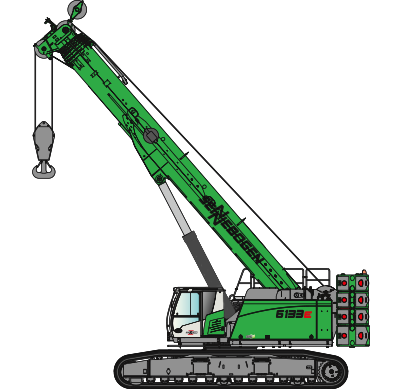

Wherever the heaviest loads have to be lifted, customers in many industries rely on Franz Bracht Kranvermietung GmbH. The long-established German crane rental company has more than 250 cranes, which enable them to handle all lifting needs in structural and civil engineering, in the wind power industry and in the demanding reinforced concrete construction, throughout Germany and in neighboring countries. In addition to several SENNEBOGEN crawler cranes, from the 4400 to the 7700, and two 683 telescopic mobile cranes with elevating cabs, which the Managing Director says are "ideal loading cranes for our machine depot in Erwitte," the company also owns several SENNEBOGEN telescopic crawler cranes, including the largest in the range to date, the 130-tonne 6133 E.

In an interview with Dirk Bracht, Managing Director of the company, SENNEBOGEN talks about the advantages of this flexible machine concept and why they specifically opted for another telescopic crawler crane from SENNEBOGEN.

SENNEBOGEN: Mr. Bracht, SENNEBOGEN telescopic crawler cranes are an integral part of your fleet. For which applications do you usually use them at your company?

Dirk Bracht: At our crane rental company, there are two main fields of application for the use of telescopic crawler cranes: The most important is the precast concrete installation. In the construction industry, our cranes are mostly on the road for regular customers with changing long-term construction sites and take on work in the area of hall or building construction, for example in the construction of DIY superstores, furniture stores or factory halls. Regarding the many equipment options, I can only recommend for these applications that the cranes should be equipped with the optional auxiliary jib in combination with the second winch for two-hook operation, so that parts can be picked up and then rotated in the air.

A second central area of application for us in rental is the wind power industry. In the wind farms, the telescopic crawler cranes act as flexible auxiliary cranes for the large lattice boom crawler cranes and are mainly used to erect and dismantle them.

SENNEBOGEN: Where do you generally see the advantages of this machine concept compared to other crane types, e.g. AT- and RT-cranes?

Dirk Bracht: The big advantage I see with the telescopic crawler cranes is the flexibility on the construction site, including above all moving under full load. While an AT-crane, for example, can only remain supported in one place and operate its certain working radius from there, with the telescopic crawler crane we can approach the target directly with the load without any restrictions. It is possible to work perfectly in confined spaces, to pass the boom flat under existing building constructions, to raise it again and slew it at the same time. The crane operator can easily move forward or backward with the full load on the hook at any time without having to leave the cab. This is not only very convenient, but also saves time. The pick & carry function is simply the trump card of all telescopic crawler cranes. Not even an RT-crane can do that.

Furthermore, the transport of a telescopic crawler crane between construction sites is also easier compared to RT-cranes – a very important point for crane rental companies like us. The fact that telecrawlers still have compact dimensions even in the performance class of 130 tons – for example a transport width of only 3.0 m – makes it possible to transport them on a standard low-loader. Dismantling the crawler tracks is not a problem here, as this flexible crane is quick and easy to erect itself thanks to its self-assembly system, and no auxiliary crane is required. With an RT-crane of this size, transport would be much more complicated, having to use a special low bed trailer.

SENNEBOGEN: Having purchased the 6133 E, why did you again opt for a telescopic crawler crane of the manufacturer SENNEBOGEN?

Dirk Bracht: We bought the SENNEBOGEN 6133 E in particular because, as a 130-tonner, it perfectly fills the gap between our existing 100- and 220-ton telescopic crawler cranes. Especially in the construction industry or for precast concrete assembly, anything less than 120 t load capacity quickly becomes too small. The 6133 E – like its somewhat smaller "brother" the 6113 E – covers this performance range perfectly.

We decided to buy another crane from SENNEBOGEN partly because we receive consistently positive feedback from our employees on these machines. The crane operators are particularly interested in the user-friendliness, the ease of maintenance and the sensitivity of the control system - all factors on which we receive only excellent feedback. Another point is that SENNEBOGEN cranes are generally very robust and reliable, so that we have virtually no breakdowns in the rental business. Should minor repairs or maintenance work nevertheless be required, we can simply fix most of it ourselves in our well-equipped and trained workshop. We are generally very satisfied with the service offered by SENNEBOGEN, although we make very little use of it for the reasons mentioned.

In my opinion, these are exactly the characteristics that distinguish SENNEBOGEN telescopic crawler cranes and SENNEBOGEN cranes in general: Extreme robustness, outstanding reliability and controllable electrics/electronics according to the motto: „Keep it simple“.

![[Translate to English:]](/fileadmin/1_Produkte/10_Raupenkran/7700/Piktogramme_Maschinenbeschriftung/7700_e_serie_raupe_NEU_01.png)

![[Translate to English:] [Translate to English:]](/fileadmin/1_Produkte/10_Raupenkran/4400/Piktogramme_Maschinenbeschriftung/4400_e_serie_raupe_NEU_01.png)